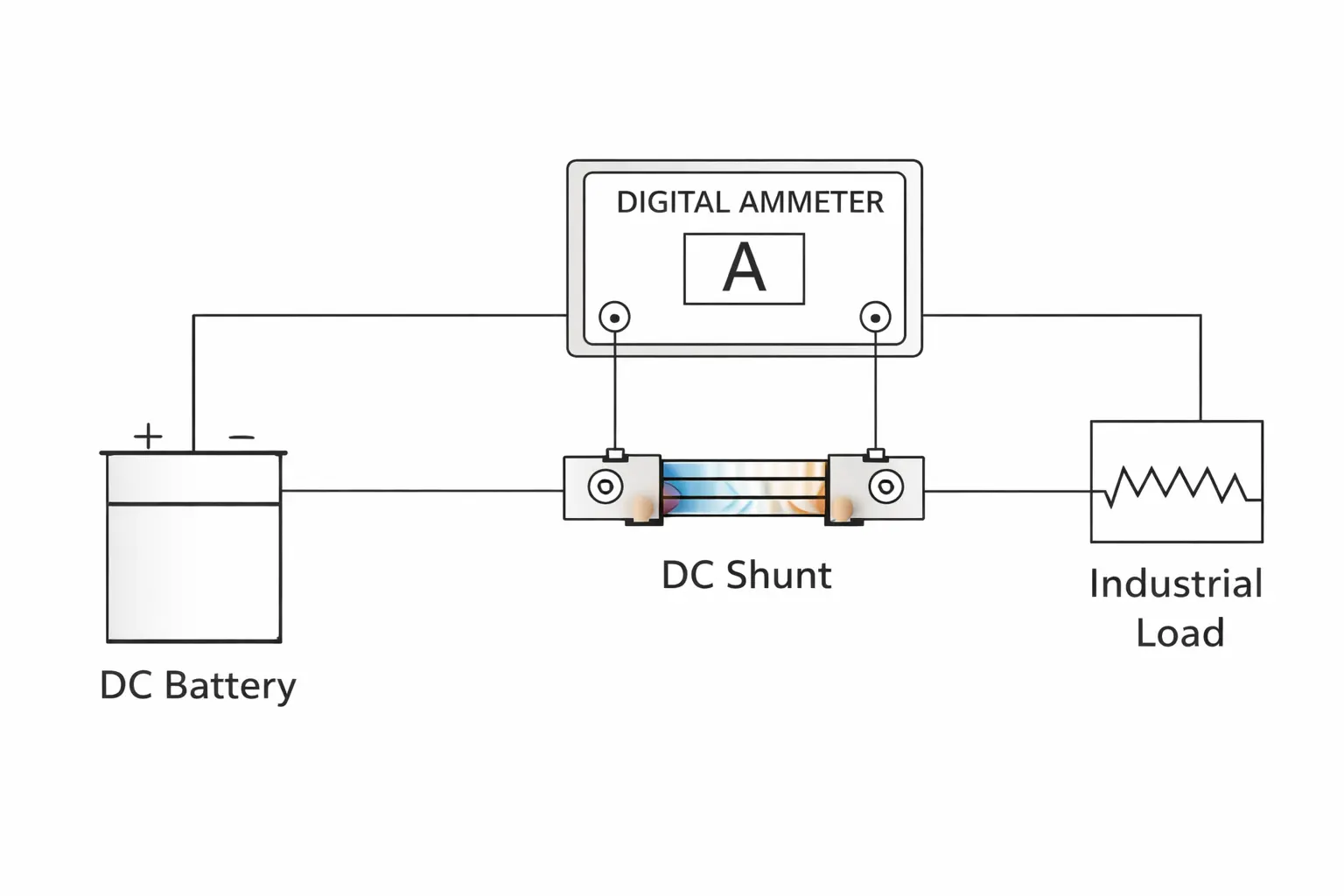

An ammeter functions alongside a dc shunt by measuring a small voltage drop created as current passes through this calibrated resistor. Industrial power designers face catastrophic equipment failure when measuring high-density energy flows without proper bypass paths. Standard measuring devices lack capacity for handling thousands of amperes without internal melting. Such hardware destruction causes immediate production downtime while safety risks multiply across your facility. But here’s the kicker—integrating our technical framework establishes operational reliability via proven bypass methodologies. Professional monitoring requires hardware built upon mathematical accuracy for protecting sensitive electronics. Ready for the good part? We provide a blueprint for implementing shunts within demanding B2B environments safely. Effective power management signifies successful project execution while reducing overall maintenance expenditures significantly. Trusting high-power monitoring requires hardware built upon mathematical accuracy for protecting sensitive electronics.

1. What constitutes the primary function of a dc shunt?

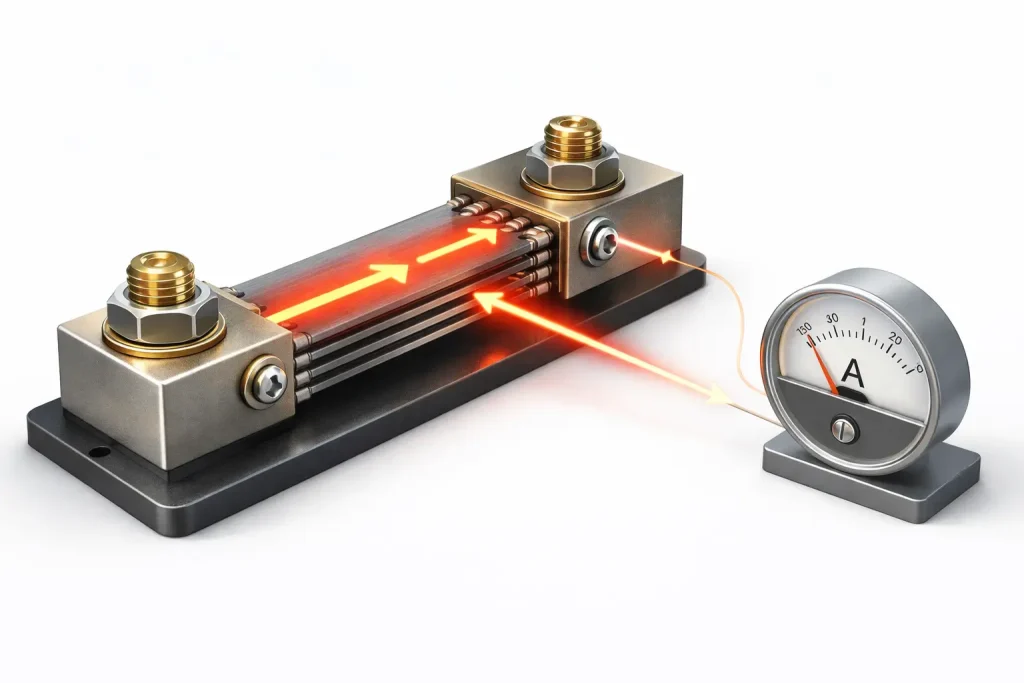

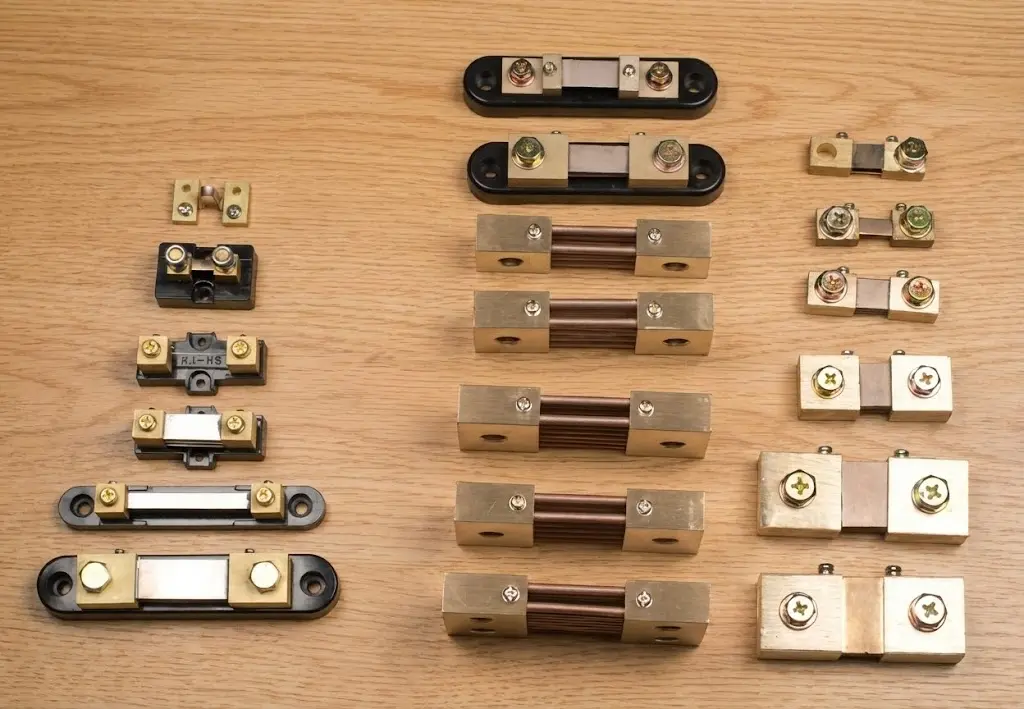

A dc shunt functions as a precision bypass path for measuring high electrical currents without damaging sensitive instruments. This hardware represents a calibrated resistance element featuring extremely low ohmic values. Here is the deal—accuracy depends upon maintaining a fixed resistance under varying heat conditions. You must select units featuring manganin strips silver-welded into heavy terminal blocks for strength.

- High accuracy

- Thermal stability

- Robust terminals

Construction ensures minimal resistance changes even when ambient temperatures fluctuate. Selecting high-quality materials signifies your commitment towards measurement integrity across every power grid. These precision resistors facilitate better control over automated manufacturing processes through reliable feedback loops. That component remains a cornerstone for safe high-voltage operations.

Diverting current through a secondary route protects primary instrumentation from thermal damage. The dc shunt carries roughly ninety-nine percent of total circuit load safely. What’s the real story? Only a tiny fraction of energy actually enters your digital ammeter. You observe this bypass principle in everything from electric vehicles until naval propulsion systems.

- Current diversion

- Instrument protection

- Heat management

Creating this secondary highway for electrons represents a genius engineering solution for high-power physics. Small measuring devices for monitoring massive turbine outputs without risk function perfectly with this setup. Professional electrical designers always prioritize high-grade shunts for ensuring long-term project success. Every measurement occurs without interrupting power delivery towards your industrial load.

Monitoring high-power loads depends entirely upon these quiet, static metal components. The dc shunt performs its task without moving parts or complex software interfaces. Think about it this way—modern green energy grids would collapse without precise current sensing. You find these resistors providing critical data for battery management systems used within solar arrays.

- Static operation

- High reliability

- Grid stability

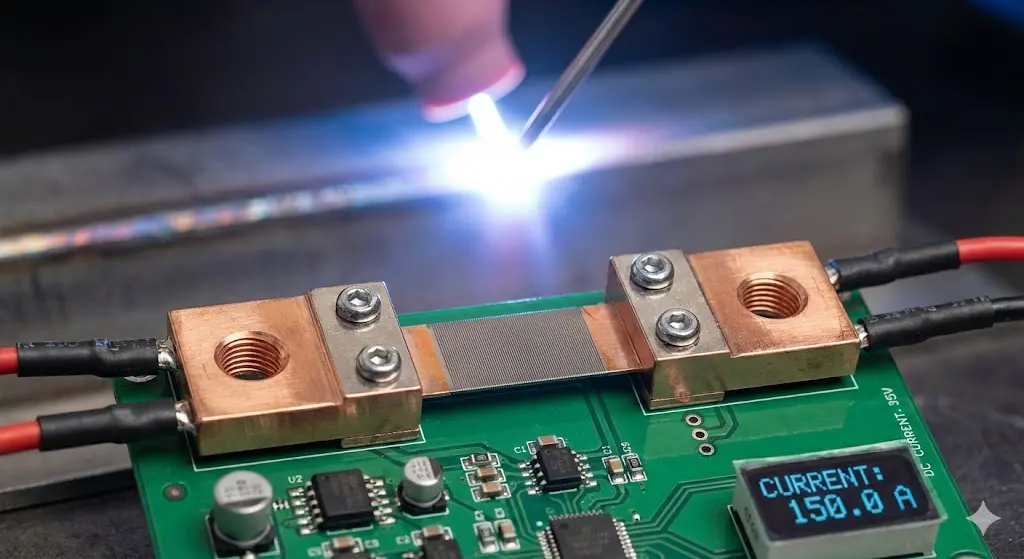

Their silent operation hides a complex manufacturing process involving precision milling plus welding. Every massive industrial welder relies upon these parts for maintaining consistent arc quality. We call them heroes because they handle heat that would vaporize other hardware. Their presence ensures that operators see accurate data before reaching dangerous load limits.

Key Takeaway: A dc shunt protects sensitive meters by diverting the majority of current through a calibrated, low-resistance path, enabling safe measurement of massive electrical loads.

| Specification | Operational Impact | |

|---|---|---|

| Resistance Value | Determines voltage drop per ampere | |

| Material Choice | Governs thermal stability and drift |

The following analysis explores how these physical components translate raw energy into readable data.

2. How does a dc shunt enable high current measurement?

A dc shunt enables measurement by creating a small, proportional voltage drop that digital ammeters interpret as current values. Measuring high current requires splitting said load between two distinct electrical paths. Ready for the good part? This guide on essentials and applications explains how electrons prefer traveling through lower resistance routes. You must understand that most energy travels through the massive metal block instead of the meter.

- Path splitting

- Voltage generation

- Load sharing

This configuration transforms massive amperage into a small, readable voltage signal for processing. Professionals use this method for monitoring systems exceeding twenty thousand amperes with ease. This enabling technology bridges the gap between raw power plus digital monitoring capabilities. Every measurement occurs without interrupting power delivery towards your industrial load or machinery.

Standard ammeters in this setup actually measure small voltage drops instead of raw current. This sensitivity allows for detecting minute changes within massive electrical power streams. What is the real story? Your meter interprets millivolts but displays them as total circuit amperes. You see this translation happen because the resistance of said shunt stays perfectly fixed.

- Millivolt sensing

- High sensitivity

- Signal interpretation

High sensitivity ensures that even small fluctuations in power become visible to operators. Such precision monitoring prevents over-load conditions before they cause permanent hardware damage. Most industrial meters work with fifty or seventy-five millivolt input signals for standardizing designs. This uniformity makes replacing meters easier across different machine brands or power systems.

Translating millivolts back into amperes requires using a specific multiplier based on shunt ratings. For example, a hundred-ampere shunt might produce seventy-five millivolts at full load. Here is the deal—the ammeter must match this specific scaling for providing accurate data. You must verify that said meter calibration matches your specific shunt output during installation.

- Scale matching

- Calibration accuracy

- Ratio calculation

Using mismatched hardware results in wildly incorrect readings plus potential system mismanagement. Such scaling factors remain constant throughout the operational life of these precision components. Digital meters allow for easy programming of these ratios for diverse hardware combinations. Precise scaling ensures that your data reflects true power usage across every circuit.

Key Takeaway: Measurement relies on converting high amperage into a tiny voltage signal (usually 50-100mV) that an ammeter can process safely and accurately.

| Rating Standard | Common Use Case | |

|---|---|---|

| 50mV Output | Compact electronic monitoring | |

| 75mV Output | Standard industrial power panels |

We must now examine the mathematical laws that govern this conversion process.

3. Why stays Ohm’s Law vital for dc shunt operation?

Ohm’s Law represents the mathematical foundation ensuring that every dc shunt generates a linear and predictable voltage signal. Calculations involving voltage plus current depend entirely upon the famous equation V equals I times R. This is where it gets interesting—the voltage drop remains directly proportional towards the current flowing through said metal. You rely upon this predictability for managing power distribution across complex factory grids.

- Linear proportionality

- Predictable output

- Mathematical rigor

This linear relationship simplifies data collection for automated industrial control systems significantly. Maintaining a fixed resistance represents the most important requirement for accurate Ohm’s Law application. Engineers rely upon this formula for calculating real-time energy usage within massive smelting plants. Without this law, current measurement would involve guesswork instead of scientific precision.

Accuracy vanishes if the resistance of your dc shunt changes during heavy usage. Heat generation represents the biggest threat towards maintaining a stable resistance value. But here’s the kicker—high-grade alloys like manganin resist thermal expansion while maintaining their electrical properties. You must prioritize stability for ensuring that Ohm’s Law remains valid under extreme load conditions.

- Resistance stability

- Thermal management

- Material integrity

A shifting resistance value would cause the ammeter for displaying incorrect current data. Such errors might lead towards premature circuit breaker tripping or dangerous over-current situations. Maintaining fixed resistance constitutes the primary goal for every high-end shunt manufacturer globally. Quality components use silver soldering for ensuring permanent electrical bonds across resistance elements.

Determining the expected millivolt output involves multiplying current by the specific shunt resistance. For a ten-ampere load through a one-milliohm shunt, you see ten millivolts. What’s the real story? This small signal represents the only information your ammeter receives during measurement. You must keep these calculations precise for ensuring automated systems respond correctly towards load changes.

- Signal calculation

- Output verification

- Error prevention

Excessive wire length can add unwanted resistance plus distort your final current reading. Keeping these calculations precise ensures that automated systems respond correctly towards load changes. Most industrial standards favor seventy-five millivolts at maximum rated current for improved signal clarity. Accurate drop calculation prevents measurement errors before they impact your industrial production cycle.

Key Takeaway: The relationship V=IR ensures that voltage increases linearly with current, allowing the ammeter to calculate amperage by measuring millivolts.

| Law Component | Shunt Equivalent | |

|---|---|---|

| Resistance (R) | Calibrated Manganin element | |

| Voltage (V) | Signal sent to the meter |

The next step involves the physical implementation of these components within a circuit.

4. How connection happens when wiring dc shunt ammeters?

Correct wiring ensures that the dc shunt sits in series with the load while the ammeter connects in parallel across the sensing terminals. The dc shunt must always sit in series with the load being monitored. Here is the deal—improper placement causes incorrect readings or immediate short circuits within your cabinet. You can find specialized u-type sampling shunt options for compact board designs.

- Series load connection

- Parallel meter wiring

- Terminal identification

Using inappropriate bolt torque leads towards high contact resistance plus excessive heat generation. Engineers must distinguish between power terminals plus sense terminals during the installation process. Said ammeter connects only towards those smaller sense screws for safety. Following strict wiring protocols ensures that your measurement system remains reliable across high-vibration environments.

Connecting measuring leads towards the wrong bolts ruins the accuracy of your readings. These small wires must attach towards the specific inner terminals provided for sensing. But here’s the kicker—using the large power bolts adds the resistance of the connection itself. You must keep sense leads short for reducing electromagnetic interference from nearby high-voltage cables.

- Sense lead precision

- Noise reduction

- Contact integrity

This extra resistance distorts the voltage signal sent towards said ammeter. Twisted pair wiring often helps for maintaining signal integrity within noisy industrial environments. Professional installers use gold-plated ring terminals for ensuring the best possible electrical contact. Correct lead placement signifies a professional approach towards high-precision electrical monitoring tasks.

Placing the dc shunt on the negative side of the battery offers maximum safety. This low-side sensing reduces common-mode voltage stress upon your sensitive measuring electronics. Ready for the good part? Most digital meters share a common ground with their power supply units. You minimize the risk of short circuits if a sense lead touches the metal chassis by using this method.

- Low-side sensing

- Safety grounding

- Chassis protection

Wiring the shunt into the positive rail requires expensive isolated measuring hardware. Low-side sensing remains the industry standard for most battery management plus solar applications. Every designer must evaluate potential fault paths before finalizing their grounding architecture. Proper strategy ensures that your monitoring system remains operational even during minor electrical faults.

Key Takeaway: Proper wiring requires series connection for the shunt and parallel connection for the meter sense leads to ensure safety and precision.

| Connection Point | Required Hardware | |

|---|---|---|

| Power Terminals | Large busbars or heavy cable | |

| Sense Terminals | Shielded twisted pair wire |

Selecting the right materials remains just as important as correct wiring for accuracy.

5. Which materials make dc shunts highly accurate?

Material selection for a dc shunt focuses on alloys that maintain constant resistance despite significant temperature fluctuations. Most high-quality units utilize manganin because of its exceptional thermal stability properties. This is where it gets interesting—this specific alloy maintains its resistance even as temperatures climb during load. You must select the right metal for preventing measurement drift that occurs with cheaper iron alternatives.

- Manganin alloy

- Thermal stability

- Drift prevention

Constantan represents another common choice for applications requiring high corrosion resistance in marine environments. Heavy copper or brass terminal blocks provide excellent conductivity plus mechanical strength for mounting. These materials ensure that the electrical connection stays cool while the resistance element works. Professional grade shunts always highlight their material composition for ensuring B2B technical compliance.

Heavy terminals must support massive cables while transferring energy towards the resistance element. Copper offers superior conductivity but remains softer than brass under heavy bolt torque. But here’s the kicker—brass provides better mechanical durability for repeated mounting plus unmounting in test labs. You must evaluate terminal mass for ensuring adequate cooling during peak power events.

- Brass durability

- Copper conductivity

- Terminal plating

Most industrial designs use silver-plated brass for combining strength with high electrical efficiency. Such plating prevents oxidation that would otherwise increase contact resistance over several years. Choosing the right terminal material ensures that your heat stays concentrated in the manganin. This thermal management keeps the rest of your electrical cabinet safe from melting.

Drift occurs when heat changes the resistance of your dc shunt during operation. This causes the ammeter for showing false data that might hide serious problems. What’s the real story? Premium materials minimize this effect through superior thermal management plus alloy stability. You find that manufacturers use sandblasting plus specialized coatings for improving heat dissipation.

- Coating efficiency

- Surface area

- Calibration window

These processes ensure that the resistance element stays within its calibrated temperature window. Preventing drift saves time on frequent recalibration tasks for your maintenance department. It also ensures that automated safety systems trip only when a real fault exists. High-quality construction signifies a commitment towards reliable data for your industrial power infrastructure.

Key Takeaway: Manganin is the gold standard for shunt elements because its resistance barely changes when the hardware gets hot under heavy loads.

| Material | Primary Advantage | |

|---|---|---|

| Manganin | Lowest temperature coefficient | |

| Silver Plating | Prevents terminal oxidation |

Material integrity also serves a critical role in protecting your secondary instrumentation.

6. Can such hardware protect ammeters from over-current?

A dc shunt acts as a sacrificial shield by diverting destructive current levels away from the sensitive internal components of an ammeter. The hardware keeps high energy away from delicate electronics by carrying most of the load. Here is the deal—even during a massive surge, the ammeter only sees a proportional millivolt increase. You can utilize the FL-IN dc shunt for meeting specific grid safety standards.

- Sacrificial shielding

- Surge mitigation

- Arc prevention

This prevents high-amperage arcs from jumping inside the meter casing during a short circuit. Such protection reduces the likelihood of fire or explosive failure within your control panel. Professional B2B systems rely upon this physical separation for maintaining safety across high-power installations. The physical mass of said shunt absorbs thermal energy that would vaporize thin meter wires.

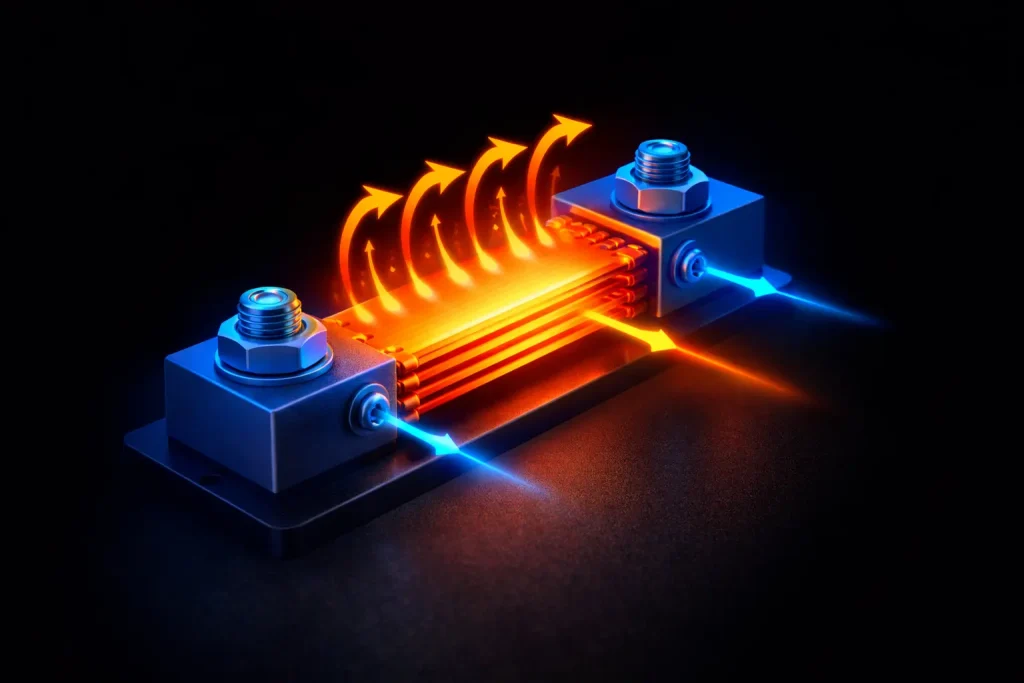

The large metal surface area of a dc shunt allows for rapid heat removal. This cooling keeps the resistance element within its safe operating temperature range during peaks. But here’s the kicker—excessive heat would otherwise radiate towards nearby sensitive control electronics. You must ensure proper mounting so airflow carries this thermal energy away from your cabinet.

- Heat dissipation

- Cooling fins

- Radiant protection

Some high-current models feature multiple metal fins for maximizing the cooling surface area. This dissipation prevents thermal runaway where rising heat causes even more resistance plus heat. Keeping the shunt cool preserves the accuracy of your ammeter readings during long shifts. Professional installers always provide enough space around shunts for ensuring natural convective cooling.

Protecting expensive meters from burnout saves significant money on replacement parts plus labor. A single dc shunt can last decades without needing replacement or complex maintenance. Ready for the good part? This durability reduces the total cost of ownership for industrial power systems. You will find that replacing a shunt is much cheaper than replacing a digital controller.

- Asset protection

- Cost efficiency

- Longevity

B2B customers prioritize hardware that minimizes system downtime due to instrument failure. Robust shunt design ensures that your monitoring stays active even after major electrical events. This reliability supports better decision-making for factory managers regarding power usage plus efficiency. Investing in high-quality shunts signifies a smart financial choice for any long-term infrastructure project.

Key Takeaway: Shunts protect ammeters by acting as a high-capacity bypass, ensuring that only a safe, low-voltage signal ever reaches the meter electronics.

| Risk Factor | Shunt Protection Method | |

|---|---|---|

| Current Surge | Massive parallel bypass path | |

| Overheating | High thermal mass and surface area |

Correct protection depends heavily on selecting the proper rating for your specific application.

7. How selection occurs for choosing right dc shunts?

Selection involves matching the maximum expected circuit current with a shunt that produces a standard millivolt output within safe thermal limits. You must match your maximum circuit current with a specific millivolt output for accuracy. This is where it gets interesting—using a slightly larger shunt provides a safety buffer against unexpected machine surges. You must also consider the physical mounting space available within your electrical cabinet.

- Current rating

- Millivolt standard

- Safety buffer

Most industrial systems follow fifty or seventy-five millivolt standards for ensuring meter compatibility. A shunt with too low a rating will overheat plus potentially melt under load. Conversely, one with too high a rating produces a weak signal that lacks precision. Professional engineers always calculate a safety margin for handling unexpected motor startup currents.

Designing for peak loads instead of average usage prevents hardware failure during stress events. Engineers apply the eighty-percent rule for ensuring that the dc shunt stays cool continuously. But here’s the kicker—a hundred-ampere shunt should only carry eighty amperes for long periods. You protect the manganin element from permanent thermal degradation by following this guideline.

- Peak load design

- Eighty-percent rule

- Thermal headroom

It also provides headroom for temporary spikes caused by large machinery starting up. Exceeding these limits risks fire or inaccurate data that could mislead operators. Safety margins represent a fundamental part of professional electrical engineering and risk management. Choosing a slightly larger shunt costs very little compared towards the price of a failure.

Harsh environments require shunts with specialized coatings or robust mechanical mounting. High vibration can loosen terminals, leading towards increased resistance plus heat. What is the real story? Selecting a beam-welded shunt offers the best durability for mobile or industrial equipment. You must verify that the environmental rating matches your specific factory floor conditions.

- Vibration resistance

- Corrosion protection

- Mechanical mounting

Reliability grows when you design systems for handling the worst-case scenario safely. Proper selection ensures that your measurement system remains both accurate plus safe for operators. Every professional designer evaluates terminal mass for ensuring adequate cooling during peak power events. Selecting appropriate hardware represents the first step towards a reliable power monitoring system.

Key Takeaway: Always choose a shunt rated for at least 125% of your continuous current to prevent overheating and maintain long-term calibration.

| System Amperage | Recommended Shunt Rating | |

|---|---|---|

| 80A Continuous | 100A Shunt | |

| 400A Continuous | 500A Shunt |

This selection process is particularly critical in modern energy storage applications.

8. Where finds dc shunt usage in battery management?

Battery management systems utilize a dc shunt to track energy flow, allowing for precise calculations of state-of-charge and battery health. The dc shunt provides the data necessary for calculating Coulomb counting within digital controllers. Here is the deal—without a shunt, your battery monitor cannot know exactly how much energy remains. You can implement a high-precision 600A dc shunt for managing large-scale storage banks.

- Coulomb counting

- State-of-charge tracking

- Energy balancing

This hardware monitors both charging plus discharging currents with equal precision for better management. We see these components in every electric vehicle powertrain for managing range plus safety. They also sit within solar inverters for balancing grid energy with stored battery power. Reliability in data leads towards better efficiency across the entire renewable energy spectrum.

Electric vehicles require massive current flows for accelerating heavy loads from a dead stop. Shunts used in these cars must handle intense vibration plus rapid temperature changes. But here’s the kicker—these components must stay extremely small for fitting within compact battery enclosures. You find that they provide the primary data for the vehicle dashboard current display.

- EV powertrain sensing

- Vibration handling

- Compact footprint

Every acceleration event generates a massive spike that the shunt must measure accurately. These parts also monitor regenerative braking current for maximizing overall driving range for consumers. Reliability in these shunts ensures that the car remains safe even during extreme driving. Materials like manganin prevent measurement errors caused by the heat of highway driving.

Large solar arrays use battery banks for providing power during nighttime or cloudy weather. The dc shunt monitors the balance between solar panel output plus building energy demand. What is the real story? It ensures that batteries don’t over-charge plus sustain permanent chemical damage. You rely upon these sensors for selling excess energy back towards the utility company.

- Solar load balancing

- Overcharge prevention

- Grid-tie monitoring

This hardware acts as the primary sensor for automated grid-tie inverter systems globally. Precise monitoring allows for selling excess energy back towards the utility company accurately. These shunts must survive years of outdoor exposure within various climates without losing calibration. Accurate data ensures that your renewable energy investment pays off through long-term performance.

Key Takeaway: Shunts are the “brain” of battery monitors, providing the raw amperage data needed to calculate exactly how much battery life remains.

| Application | Critical Metric | |

|---|---|---|

| Electric Vehicles | Real-time acceleration load | |

| Solar Storage | Daily charge/discharge cycles |

Diverse applications have led to the development of many specialized shunt varieties.

9. What varieties exist among available dc shunt types?

DC shunt varieties range from standard industrial blocks to compact board-mounted units designed for specialized electronic sampling. Choosing the right type depends upon your specific regional standards plus application requirements. This is where it gets interesting—the FL-2 series remains the standard for many Chinese industrial manufacturing projects. You must verify that the chosen model matches your local electrical code requirements.

- FL-series standards

- Regional compliance

- Mounting flexibility

Specialized U-type shunts provide compact sensing for modern high-power printed circuit boards in electronics. Every type features unique mounting holes plus terminal designs for specific cabinet layouts. Professional buyers must verify that the chosen model matches their local electrical code requirements. This variety ensures that every project finds a perfect match for its current sensing needs.

Modern electronics require current sensing directly upon the circuit board for better control. U-type shunts offer a compact footprint for integrating into high-density power modules. But here’s the kicker—their shape allows them for standing tall while saving valuable horizontal board space. You find these parts machine-soldered during the automated assembly of industrial motor drives.

- PCB integration

- Space optimization

- Automated assembly

They provide the necessary feedback for precision speed control plus over-current protection. Despite their small size, they maintain high accuracy through precision-milled resistance paths. Engineers value them for their ability for reducing the overall size of power electronics. They represent a key technology for the miniaturization of modern industrial automation hardware.

Sometimes standard models don’t fit the unique requirements of a specialized machine. Custom shunts allow for specific dimensions, bolt patterns, plus millivolt outputs for designers. What is the real story? You can request specialized coatings or materials for extreme environmental conditions like mines. You must collaborate with manufacturers for validating the thermal performance of new designs.

- Custom dimensions

- Specialized coatings

- Proprietary integration

Customization ensures that the shunt integrates perfectly with your proprietary cooling systems or enclosures. Manufacturers work closely with your engineering team for validating the thermal performance of new designs. This collaboration prevents integration issues that could delay your project launch for months. Custom hardware signifies a premium approach towards solving complex current sensing challenges.

Key Takeaway: From standard FL-series to custom U-types, selecting the right physical form factor is as important as choosing the correct electrical rating.

| Shunt Variety | Best Use Case | |

|---|---|---|

| FL-2 Block | Panel-mount industrial use | |

| U-Type | High-density circuit boards |

Finalizing a design requires a plan for long-term maintenance and stability.

10. How maintenance ensures long-term dc shunt stability?

Maintenance involves regular cleaning and thermal inspections to prevent contact resistance from degrading the accuracy of the dc shunt. While these parts feature no moving elements, they still require regular inspection for safety. Here is the deal—dirt plus oxidation can increase contact resistance between the cable plus the shunt. You must verify the torque on mounting bolts for preventing loose connections.

- Oxidation removal

- Torque verification

- Contact cleaning

This extra resistance generates heat that can damage nearby wires or components. Regular cleaning ensures that the millivolt signal sent towards your ammeter stays accurate. Thermal imaging helps maintenance teams for identifying hotspots before they lead towards system failure. A well-maintained shunt ensures that your power data remains trustworthy for years of operation.

Using infrared cameras allows you for seeing heat patterns during peak load periods. The dc shunt should show a uniform heat distribution across its resistance elements. But here’s the kicker—a hot terminal indicates a poor connection or internal metal fatigue. You identify these issues early for preventing catastrophic failure during a critical production run.

- Infrared inspection

- Heat uniformity

- Predictive repair

Proper cooling remains vital for maintaining the calibrated accuracy of the manganin strips. If the shunt stays too hot, your current readings will start towards drift significantly. Monitoring heat also protects the insulation of nearby power cables from melting or charring. Professional maintenance teams keep detailed thermal logs for tracking the health of their power systems.

Even high-quality shunts can experience slight changes in resistance after many years of service. Environmental factors like humidity or corrosive gases can slowly affect the metal surface. Ready for the good part? Regular calibration verifies that your ammeter still displays the true circuit current. You should schedule a calibration check every two until five years.

- Calibration verification

- Reference standards

- Accuracy logging

This process involves comparing your shunt against a laboratory-grade reference standard for accuracy. Calibration certificates provide the necessary documentation for quality audits plus insurance compliance. It ensures that your automated systems are making decisions based on clean data. Trusting your measurements requires a commitment towards periodic verification by certified technicians.

Key Takeaway: Periodic maintenance—specifically checking bolt torque and cleaning terminals—is essential for preventing heat-related accuracy loss over time.

| Maintenance Task | Frequency | |

|---|---|---|

| Bolt Torque Check | Every 6 months | |

| Accuracy Calibration | Every 2-5 years |

Integrating a dc shunt with an ammeter provides a robust solution for high-current monitoring. This configuration protects sensitive electronics while delivering accurate data through Ohm’s Law principles. Materials like manganin ensure thermal stability across diverse industrial environments globally. Proper wiring plus selection are vital for maintaining system safety plus long-term reliability. Trusting professional-grade hardware signifies a commitment towards engineering excellence for your project. Please contact us today for expert guidance on your next power management installation.

PREGUNTAS FRECUENTES

Q1: What is a dc shunt?A dc shunt represents a precision resistor with very low resistance used to measure high currents by creating a proportional voltage drop. This part allows a sensitive meter for displaying large amperage values safely.

Q2: How does a dc shunt work?A dc shunt works by diverting most of the circuit current through its heavy metal body while sending a tiny millivolt signal towards the ammeter. This follows Ohm’s Law where voltage drop functions directly proportional towards current.

Q3: Can I cut or modify a dc shunt to change its resistance?No, modifying a dc shunt destroys its factory calibration and leads towards inaccurate measurements. Even minor physical changes towards the manganin element significantly alter the resistance value.

Q4: What is the best material for high-temperature environments?Manganin serves as the best material for high-temperature environments due towards its exceptionally low-temperature coefficient. This component maintains constant resistance even as the hardware heats up during heavy loads.

Q5: Can I mount a dc shunt in any orientation?Yes, you can mount a dc shunt in any orientation, but horizontal mounting remains preferred for better natural cooling. This allows heat for rising away from the resistance element effectively.