In a time when there are many enterprises dependent on constant energy and sensitive technology, lightning strikes pose a bigger threat than ever. Transformers, communication systems, and industrial lines can all be severely damaged by a single surge, resulting in millions of dollars in lost productivity. Lightning arrester manufacturers are unsung heroes in this conflict, creating machines that subtly divert the wrath of nature from vital infrastructure. But in a market flooded with options, how do industry professionals identify manufacturers that blend innovation with reliability?

This guide dives deep into the evolving world of lightning protection, unpacking the technology, standards, and strategic insights needed to choose partners who prioritize safety over shortcuts.

The Growing Imperative for Lightning Protection

Climate change has increased the frequency and intensity of thunderstorms, with the National Lightning Safety Institute reporting a 15% rise in lightning-related industrial damage since 2015. Meanwhile, industries are adopting IoT-driven systems and renewable energy grids—technologies hypersensitive to voltage spikes.

Lightning arrester manufacturers are no longer just suppliers; they’re strategic allies in risk management. Their products act as insurance policies against:

- Equipment Destruction: A 2023 study found that 68% of power grid failures in hurricane-prone regions were surge-induced.

- Data Loss: Telecom towers without robust arresters face a 40% higher risk of signal disruption during storms.

- Regulatory Non-Compliance: Failing to meet IEC 62305 standards can result in hefty fines and voided insurance claims.

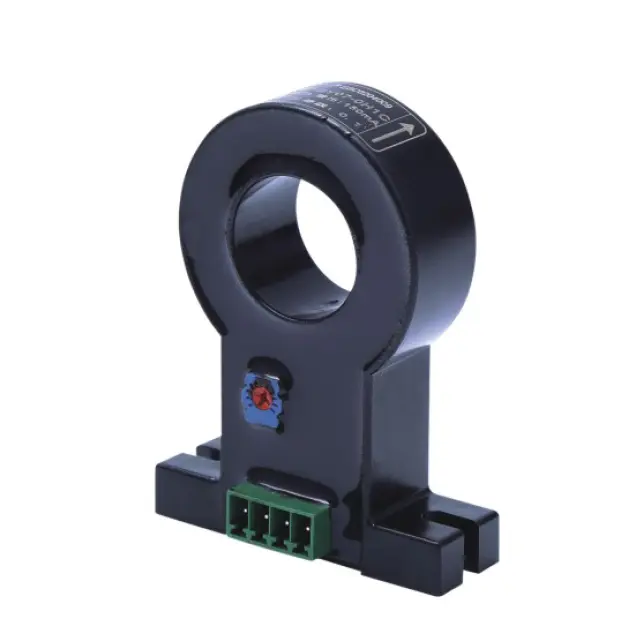

Decoding Lightning Arrester Technology: From Spark Gaps to Smart Sensors

A Brief History

Simple spark gaps were utilized in the 19th century to redirect surges in the earliest lightning arresters. Although efficient at the time, they were unable to manage the complexity of the current grid. With its increased energy absorption and quicker reaction times, metal oxide varistors (MOVs) revolutionized surge prevention in the 1970s.

How Modern Arresters Work

Today’s devices rely on zinc oxide (ZnO) blocks stacked in series. Under normal conditions, these blocks act as insulators. When a surge exceeds the threshold voltage, their resistance drops instantaneously, channeling current to the ground. Post-surge, they revert to insulating mode—all within nanoseconds.

Key components:

- ZnO Varistors: The “brain” that detects and reacts to surges.

- Polymer Housing: Lightweight, shatterproof, and resistant to UV/chemical degradation.

- Sealing Systems: Prevent moisture ingress, the #1 cause of arrest failure.

Top lightning arrester manufacturers enhance this base design with innovations like hydrophobic coatings and embedded IoT sensors for real-time health monitoring.

Choosing Lightning Arrester Manufacturers: A 10-Point Checklist for Industry Professionals

Selecting a manufacturer isn’t just about specs—it’s about aligning with partners who understand your operational risks. Here’s a detailed framework:

1. Certifications Beyond the Basics

Look for:

- IEC 60099-4 (Standard for Surge Arresters)

- IEEE C62.11 (Metal-Oxide Arresters for AC Systems)

- ISO 9001 (Quality Management)

Pro Tip: Manufacturers compliant with ANSI/IEEE standards are better suited for North American grids.

2. Material Traceability

Demand transparency in sourcing:

- Zinc Oxide Purity: ≥99.9% for optimal nonlinear characteristics.

- Polymer Housing: UV-stabilized silicone rubber with a track record in harsh environments (e.g., coastal or desert installations).

3. Custom Engineering Capabilities

Can the manufacturer adjust parameters like:

- MCOV (Maximum Continuous Operating Voltage): Critical for solar farms with variable loads.

- Discharge Current Capacity: Up to 100kA for high-risk zones like oil refineries.

For example, advanced systems allow customization of monitoring interfaces to integrate with SCADA systems—a must for smart grids.

4. Testing Rigor

Beyond standard impulse tests, leading lightning arrester manufacturers conduct:

- Accelerated Aging Trials: Simulating 20 years of service in 1000 hours.

- Partial Discharge Tests: Ensuring no internal defects.

- Pressure Relief Tests: Validating explosion-proof claims.

5. Industry-Specific Expertise

- Utilities: Focus on arresters for 400kV+ transmission lines.

- Renewables: Look for DC arresters compatible with solar/wind farms.

- Data Centers: Prioritize ultra-fast (<25ns) response times.

6. Sustainability Practices

Eco-conscious partners should:

- Use recyclable polymer housings.

- Employ low-carbon manufacturing processes.

- Offer take-back programs for end-of-life units.

7. Global Support Network

A manufacturer with service centers in your region ensures:

- Faster replacements during emergencies.

- Localized technical support for maintenance.

8. Transparent Documentation

Request:

- Third-party test reports (e.g., KEMA Labs).

- Detailed failure mode analysis (FMA) for past projects.

9. Total Cost of Ownership (TCO) Analysis

Cheaper arresters may save upfront but cost more in replacements.

Calculate:

TCO = Initial Cost + (Replacement Frequency × Downtime Cost)

A 2022 study in IEEE Transactions showed that high-quality arresters reduced TCO by 34% over a decade.

10. Future-Proofing

Ask: Are they investing in AI-driven predictive maintenance or biodegradable materials?

Case Studies: Lessons from the Field

Case 1: Offshore Wind Farm, North Sea

Challenge: Salt spray corrosion caused traditional porcelain arresters to fail within 2 years.

Solution: A manufacturer provided polymer-housed units with anti-corrosive coatings.

Result: 7+ years of service with zero surge-related downtime.

Case 2: Data Center in Florida

Challenge: Lightning strikes disrupted servers despite having arresters.

Root Cause: Arresters had slow response times (50ns), allowing residual surges.

Solution: Upgraded to high-speed models with 15ns response.

Result: Annual surge incidents dropped from 12 to 0.

The Cost of Cutting Corners: Risks of Substandard Arresters

A chemical plant in Texas learned this the hard way. To save $20,000 upfront, they chose uncertified arresters. During a storm:

- A surge bypassed the arrester, destroying a $2.8 million transformer.

- Production halted for 11 days, costing $5.3 million in lost revenue.

- Insurance denied the claim due to non-compliant equipment.

Key Takeaway: The plant’s “savings” cost 375x more than investing in certified arresters.

The Future: 5 Trends Reshaping Lightning Protection

- Smart Arresters with Edge Computing

Sensors now analyze surge patterns, predict failures, and send alerts via cloud platforms. - Graphene-Enhanced Varistors

Early trials show graphene-ZnO composites can handle 30% higher energy densities. - Self-Healing Housing

Polymers that autonomously repair minor cracks caused by thermal cycling. - DC Microgrid Solutions

As solar/battery systems proliferate, DC arresters are becoming a niche focus. - Blockchain for Supply Chain Transparency

Manufacturers like Leeydtech use blockchain to trace raw materials from mine to the assembly line.

FAQs: Addressing Industry Professionals’ Key Concerns

Q1: Which material is used in lightning arresters?

Lightning arrester manufacturers mainly use zinc oxide (ZNO) varists for their better energy absorption and rapid response. Housing is usually silicon rubber or EPDM polymer for durability. Porcelain, while still used in some high-voltage applications, is being phased due to weight and fragility.

Q2: What is the most common defect of a lightning arrester?

Moisture ingress accounts for 52% of failures (per CIGRE 2023 data). Even microscopic cracks in housing can allow humidity to corrode internal ZnO blocks. Top manufacturers combat this with:

- Hermetic sealing using laser-welded aluminum.

- Silica gel breathers to control internal humidity.

- Annual thermographic inspections to detect early cracks.

Q3: How to calculate lightning arrester rating?

Follow this 4-step process:

- Determine System Voltage: E.g., 33kV, 132kV, etc.

- Calculate MCOV:

MCOV = (System Voltage × 1.05) / √3

- Assess Fault Current: Use historical lightning density maps (e.g., IEC 62305-2) for your region.

- Add Safety Margin: Select an arrester with 20-25% higher discharge capacity than calculated.

For complex sites like substations, consult manufacturers offering custom rating services.

Q4: How often should arresters be replaced?

- Polymer Arresters: 15-20 years (with annual inspections).

- Porcelain Arresters: 10-15 years.

Replace immediately if: - Visual damage (cracks, discoloration) is present.

- Monitoring systems show leakage current exceeding 1mA.

Q5: What’s the difference between Class 1 and Class 2 arresters?

- Class 1 (High Exposure): Handles direct lightning strikes (10/350μs waveform). Used in telecom towers.

- Class 2 (Medium Exposure): Manages induced surges (8/20μs). Common in residential/commercial buildings.

Final Thoughts: Partnering for Long-Term Resilience

In lightning protection, there’s no room for compromise. Industries may turn surge arresters from cost centers into strategic assets by selecting lightning arrester manufacturers who combine state-of-the-art research and development with constant quality control.

The collaborations you establish now will dictate how resilient your infrastructure is in the future as storms get more intense and grids become smarter. Remember that readiness is your best ally when the skies scream, be educated, and expect perfection.