The industrial sector represents one of the largest markets for DC current shunts, with applications spanning manufacturing, power distribution, process control, and automation systems. This article explores the diverse industrial applications of DC shunts, their technical requirements, and best practices for implementation in demanding industrial environments.

The Critical Role of DC Shunts in Industrial Settings

Industrial environments require precise current measurement for process control, equipment protection, and energy management. DC current shunts serve as reliable, cost-effective solutions for these applications, offering several advantages over alternative technologies in harsh industrial conditions.

Why DC Shunts Excel in Industrial Applications

DC shunts provide several crucial benefits in industrial settings:

- Robustness: Withstand harsh environments, vibration, and temperature variations

- Reliability: Simple design with no moving parts ensures long-term dependability

- Accuracy: Precise measurements across wide current ranges

- Cost-effectiveness: Lower initial and lifetime costs compared to alternative technologies

- Simplicity: Straightforward installation and integration with existing systems

- Longevity: Typical service life of 15-20+ years with proper installation

Key Industrial Applications for DC Shunts

Power Distribution and Management

Industrial facilities consume significant electrical power, requiring careful monitoring and management.

Applications in power distribution:

- Main service entrance monitoring: Measuring facility-wide power consumption

- Load monitoring: Tracking power usage of major equipment and production lines

- Power quality analysis: Providing data for power factor correction and efficiency improvements

- Demand management: Supporting peak demand reduction strategies

| Application | Typical Current Range | Recommended Shunt Specifications |

|---|---|---|

| Main service entrance | 500-5000A | 0.5% accuracy, 50-100mV output |

| Distribution panels | 100-1000A | 0.5% accuracy, 50-75mV output |

| Individual equipment | 20-500A | 0.5-1.0% accuracy, 50-75mV output |

| Critical process lines | 50-1000A | 0.2-0.5% accuracy, 75mV output |

Motor Control Systems

Electric motors power countless industrial processes. DC shunts play a vital role in motor control and protection.

Motor control applications:

- Current feedback for VFDs: Providing accurate current measurement for variable frequency drives

- Overload protection: Detecting excessive current draw

- Process control: Correlating motor current with process parameters

- Predictive maintenance: Monitoring current patterns to detect issues

| Motor Size | Typical Current | Shunt Requirements |

|---|---|---|

| Small (1-10HP) | 1.5-15A | 0.5-1.0% accuracy, standard temp stability |

| Medium (10-100HP) | 15-150A | 0.5% accuracy, good temp stability |

| Large (100-1000HP) | 150-1500A | 0.2-0.5% accuracy, excellent temp stability |

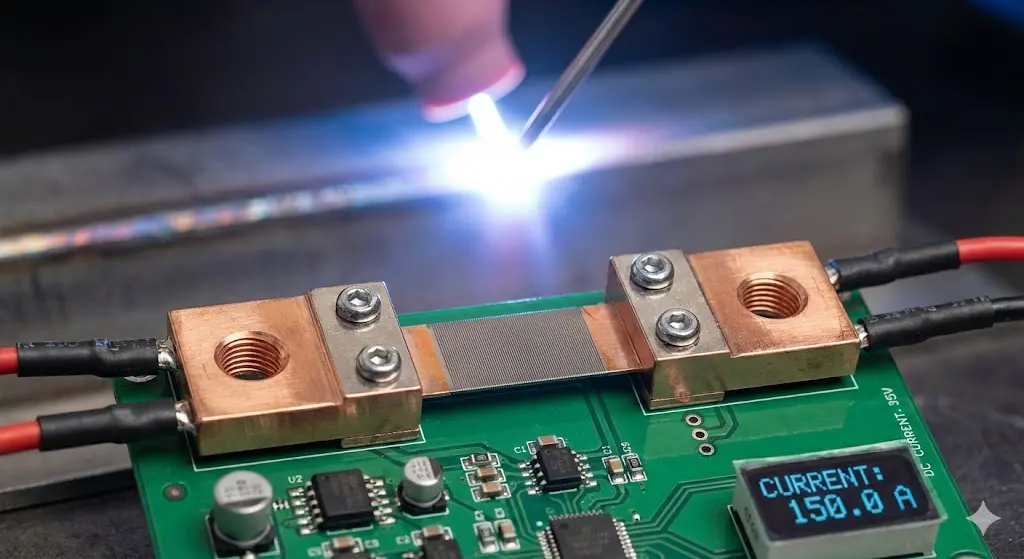

Welding Equipment

Industrial welding requires precise current control. DC shunts are fundamental components.

Welding applications:

- Process control: Maintaining consistent welding current

- Quality assurance: Verifying proper current delivery

- Equipment protection: Preventing overcurrent

- Performance monitoring: Tracking equipment performance

| Welding Process | Current Range | Shunt Specifications |

|---|---|---|

| MIG/MAG welding | 50-500A | 0.5% accuracy, 75-100mV output |

| TIG welding | 5-300A | 0.2-0.5% accuracy, 50-75mV output |

| Stick welding | 50-400A | 0.5% accuracy, 75mV output |

| Spot welding | 1000-10000A | 0.5-1.0% accuracy, 50-100mV output |

Electroplating and Surface Treatment

These processes require precise current control for consistent coating thickness and quality.

Electroplating applications:

- Current regulation: Maintaining precise current density

- Process verification: Confirming proper current delivery

- Recipe management: Supporting different current profiles

- Efficiency optimization: Minimizing power consumption

Battery Charging and Testing

Industrial battery systems require accurate current monitoring.

Battery applications:

- Charge control: Ensuring proper charging profiles

- Discharge monitoring: Tracking performance under load

- Capacity testing: Measuring current during verification

- Health assessment: Analyzing patterns to evaluate condition

Process Control and Automation

Modern automation systems rely on accurate current measurements.

Automation applications:

- Feedback control loops: Providing current data

- Process verification: Confirming proper equipment operation

- Fault detection: Identifying abnormal current patterns

- Data acquisition: Collecting data for analysis and optimization

Technical Requirements for Industrial DC Shunts

Industrial environments present unique challenges:

Environmental Considerations

Industrial settings expose equipment to harsh conditions:

- Temperature extremes

- Humidity and moisture

- Dust and contaminants

- Vibration

- Electrical noise

Environmental specifications typically required:

- Operating temperature range: -20°C to +80°C (or wider)

- IP54 or higher protection rating

- Vibration resistance (IEC 60068-2-6)

- EMC compatibility (IEC 61000)

Accuracy and Measurement Requirements

Varying accuracy needs:

- General monitoring: 0.5-1.0% accuracy

- Process control: 0.2-0.5% accuracy

- Precision applications: 0.1-0.2% accuracy

- Temperature stability: Critical in varying temperatures

Physical and Installation Requirements

Space and installation considerations:

- Form factor: Compact designs

- Mounting options: DIN rail, panel mount, bus bar

- Connection type: Compatibility

- Accessibility: Ease of installation/maintenance

Comparison with Alternative Current Measurement Technologies

Alternatives are used in specific situations:

| Technology | Advantages | Disadvantages | Industrial Applications |

|---|---|---|---|

| DC Shunts | Robust, reliable, cost-effective, high accuracy | Power loss, no isolation, heating | General monitoring, motor control, welding |

| Current Transformers | Isolation, no insertion loss, AC only | Cannot measure DC, saturation | AC monitoring, protection systems |

| Hall Effect Sensors | Isolation, AC/DC, compact | Temp drift, higher cost, limited accuracy | VFDs, sensitive electronics, low-power |

| Rogowski Coils | No saturation, wide range, isolation | AC only, complex integration | High-current AC, temporary measurements |

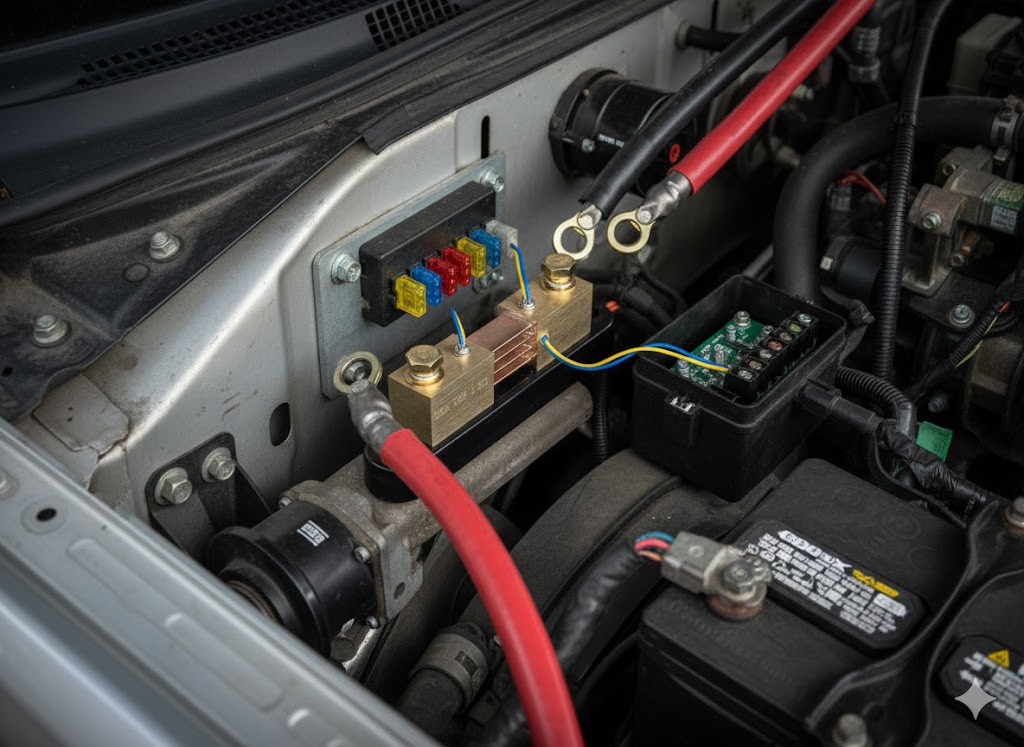

Installation Best Practices

Proper installation is critical:

Mounting Guidelines

- Location: Accessible, away from extreme heat

- Orientation: Follow manufacturer recommendations

- Ventilation: Ensure adequate airflow

- Protection: Consider enclosures in harsh environments

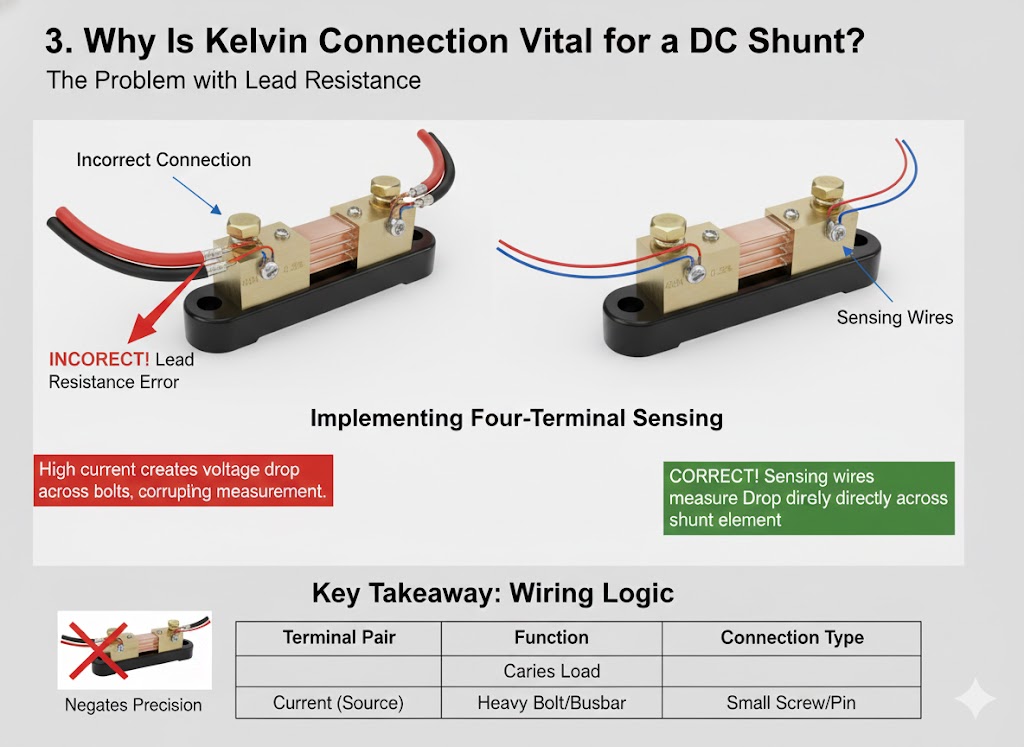

Connection Best Practices

- Sizing: Use appropriate cables/bus bars

- Cleanliness: Ensure clean, corrosion-free surfaces

- Torque: Follow manufacturer specifications

- Treatment: Apply anti-corrosion compounds if needed

Measurement Circuit Considerations

- Cable: Use shielded cables

- Routing: Keep away from power cables/interference

- Termination: Ensure proper termination

- Protection: Consider surge protection

Maintenance and Troubleshooting

Regular maintenance ensures reliability:

Preventive Maintenance Schedule

| Component | Inspection Frequency | What to Check |

|---|---|---|

| Shunt connections | Quarterly | Tightness, corrosion, discoloration |

| Shunt body | Semi-annually | Damage, discoloration, overheating signs |

| Measurement connections | Quarterly | Secure connections, wire condition |

| Enclosure | Quarterly | Dust, ventilation blockage |

Common Issues and Solutions

- Inaccurate readings: Check connections, circuit integrity, corrosion, calibration.

- Overheating: Verify current rating, ventilation, connection resistance. Consider upgrade.

- Noise in measurements: Improve shielding, grounding, cable routing. Consider filtering.

Case Studies: DC Shunts in Industrial Applications

Case Study 1: Steel Manufacturing Plant

Implemented DC shunts (5000A main, 1000A distribution, 200-500A equipment) for power monitoring. Results:

- 12% reduction in energy costs

- Early detection of equipment issues

- Improved load balancing

Case Study 2: Automotive Manufacturing

Used 1000A DC shunts in robotic welding cells for current control. Results:

- Improved weld consistency and quality

- Reduced rework rates by 15%

- Enabled predictive maintenance on welding equipment

Frequently Asked Questions (FAQ)

Q1: How do I choose between a 50mV, 75mV, or 100mV shunt for an industrial application?

A1: Consider your measurement equipment sensitivity and acceptable power loss. 75mV is common. 50mV has lower loss, while 100mV provides a stronger signal.

Q2: Can DC shunts be used in hazardous industrial environments?

A2: Yes, but they must be appropriately rated and often installed within certified explosion-proof enclosures for hazardous locations.

Q3: How does vibration affect DC shunt performance?

A3: Excessive vibration can loosen connections, leading to inaccurate readings or overheating. Choose shunts rated for industrial vibration levels and ensure secure mounting.

Q4: Is temperature compensation necessary for industrial DC shunts?

A4: It depends on the required accuracy and operating temperature range. For high-precision applications or wide temperature swings, shunts with low temperature coefficients (e.g., Manganin) or external compensation are recommended.

Q5: How can I integrate DC shunt measurements into a PLC or SCADA system?

A5: The millivolt output from the shunt can be connected to an analog input module on a PLC or RTU. Signal conditioners can convert the mV signal to standard 4-20mA or 0-10V signals if needed. Some modern shunts offer direct digital outputs (e.g., Modbus).

Conclusion

DC current shunts are workhorses in the industrial sector, providing reliable and accurate current measurements essential for power management, process control, equipment protection, and automation. Their robustness, cost-effectiveness, and simplicity make them ideal for demanding industrial environments. Proper selection, installation, and maintenance are key to leveraging their full potential in optimizing industrial operations.