In the world of industrial welding, consistency is everything. You want the first weld of the day to look exactly like the last one. But have you ever wondered how a welding machine knows exactly how much power it is pushing? The secret lies in a component that often goes unnoticed but does the heavy lifting: the dc current shunt.

Think of the welding machine as the “muscle” and the control board as the “brain.” The dc current shunt is the nervous system that connects them. Without it, the brain has no idea what the muscle is doing.

What Does a DC Current Shunt Actually Do?

In simple terms, a dc current shunt is a translator.

Welding requires massive amounts of electricity—sometimes hundreds or thousands of amps. A delicate computer control board cannot handle that kind of power directly; it would fry instantly.

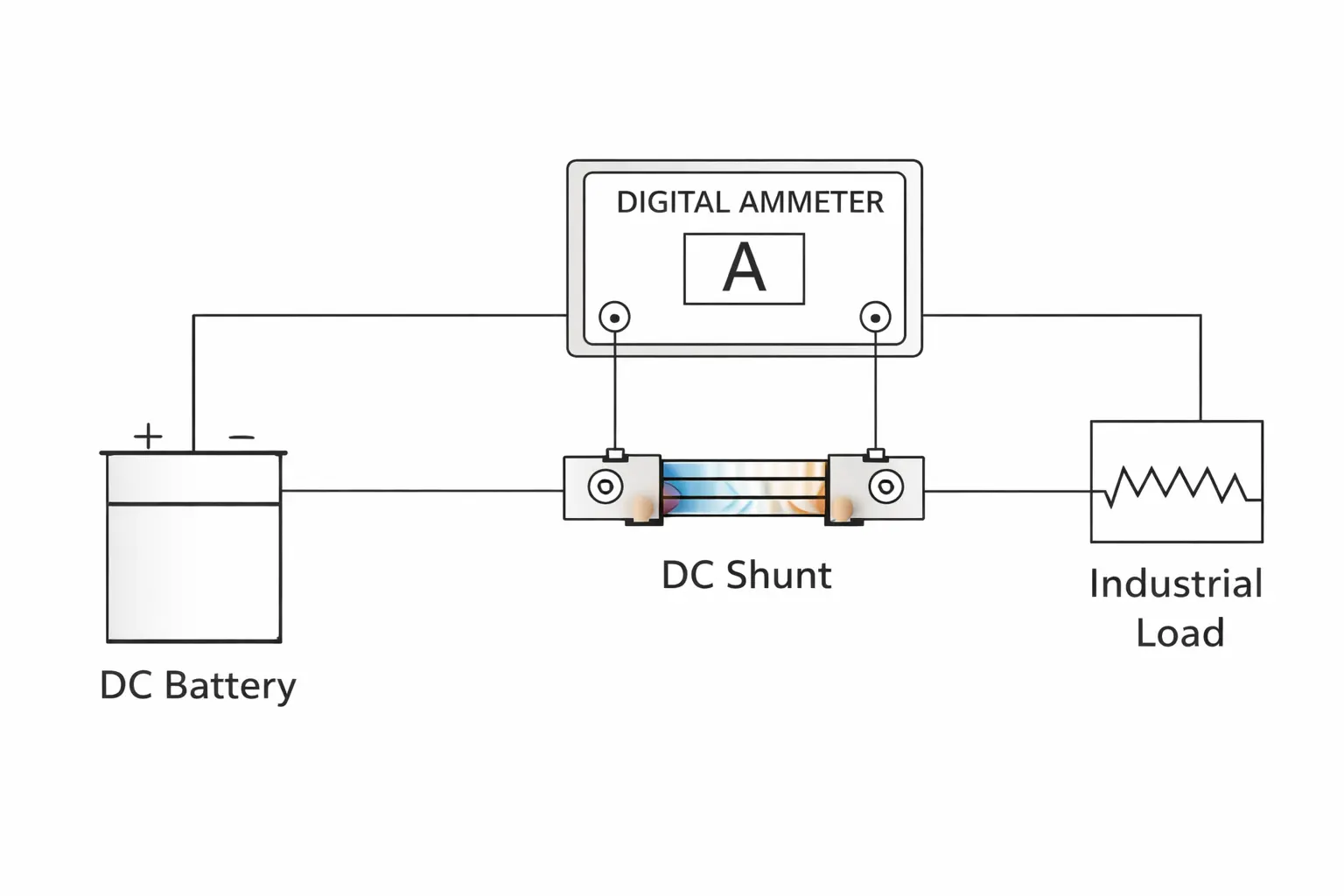

The shunt sits in the main power line. As the massive welding current flows through it, the shunt converts that high current into a tiny, safe voltage signal (usually measured in millivolts). The control board reads this safe signal to understand exactly what is happening at the welding arc.

Why is this vital?

Accurate Feedback: It tells the machine, “You are outputting 200 Amps.”

Real-Time Control: If the arc length changes, the shunt signals the change instantly, allowing the machine to adjust.

The Consequence of Bad Feedback

Imagine driving a car with a broken speedometer. You might be going too fast or too slow without realizing it.

The same happens in welding. If the dc current shunt provides inaccurate data:

- Arc Stability suffers: The arc may stutter or flare up unexpectedly.

- Inconsistent Penetration: The weld might not go deep enough into the metal, leading to structural weakness.

- Failed Inspections: For aerospace or structural projects, logged data must match reality. Inaccurate shunts lead to failed ISO or AWS audits.

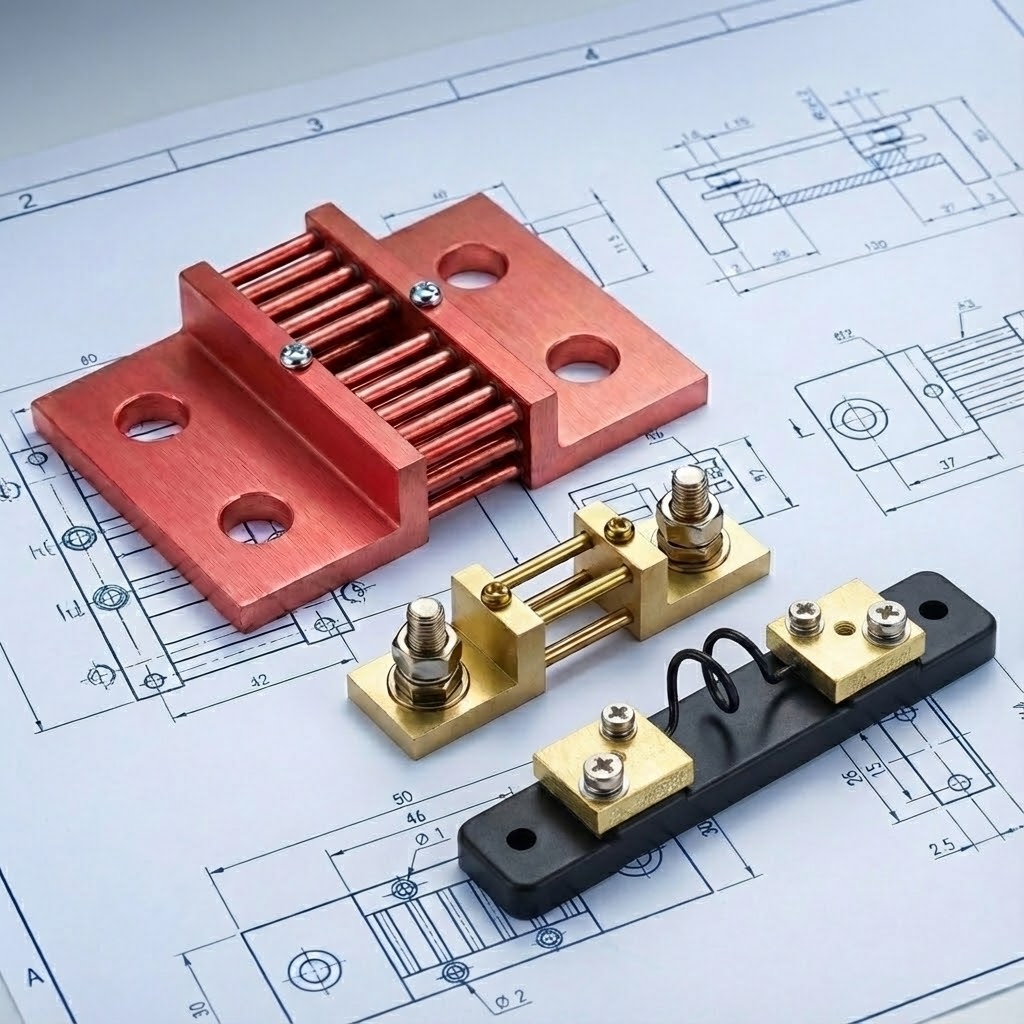

How to Select the Right DC Current Shunt

Choosing the right shunt isn’t just about picking a number. It is about safety and longevity.

1. The 20% Safety Rule

Never pick a shunt that matches your machine’s maximum output exactly. If your welder outputs 500 Amps, a 500 Amp shunt is running at 100% capacity—this causes overheating.

Best Practice: Always add a 20% safety margin. If you need 500 Amps, choose a dc current shunt rated for at least 600 Amps. This handles heat buildup and sudden ignition surges (spikes in power) without damage.

2. Handling Pulse Welding

Modern welding often uses “pulsed” current, which switches rapidly between high and low power. Standard resistors can’t keep up. You need a precision shunt with high “thermal mass” to absorb these spikes without distorting the signal.

| Selection Factor | Why It Matters | Recommended Action |

| Amperage Rating | Prevents overheating and drift | Select rating 20% higher than max output |

| Duty Cycle | Handles continuous running time | De-rate for high ambient temperatures |

| Inductance | Critical for high-frequency inverters | Choose low-inductance designs |

Thermal Stability: The Battle Against Heat

All metal gets hot when electricity flows through it. The problem is that most metals change their resistance when they get hot. This is called “Resistance Drift.”

If your dc current shunt drifts, the machine thinks it is outputting 100 Amps, but it might actually be outputting 110 Amps.

The Manganin Solution: High-quality shunts use a special alloy called Manganin.

- Feature: It maintains the exact same resistance whether it is 25°C (room temp) or 80°C (hot).

- Benefit: Your welds stay consistent from the cool morning start to the end of a hot shift.

Installation: How to Connect It Properly

Even the best dc current shunt will fail if installed incorrectly. The most common mistake is the wiring.

The Kelvin Connection (4-Terminal Sensing)

You will notice a precision shunt has four connection points, not two.

- Big Terminals: For the heavy welding cables (Current).

- Small Screws: For the thin sensing wires (Voltage).

You must keep these separate. This setup, called a Kelvin Connection, ensures the sensing wires only read the shunt itself, ignoring the interference from the bolts or cables.

Location and Cooling

- Airflow: Mount the shunt where the welder’s fan can blow on it.

- Orientation: Mount it vertically (fins up) so heat can rise away from it naturally.

- Torque: Loose bolts create heat. Use a torque wrench to tighten the main terminals to spec.

Troubleshooting Common Issues

Is your feedback acting strange? Here is how to diagnose the problem.

| Symptom | Probable Cause | The Fix |

| Hot Terminals | Loose connection or oxidation | Clean copper surface and re-torque bolts |

| Discolored Element | Overloading / Undersized shunt | Upgrade to a higher amperage rating |

| Erratic Signal | Electromagnetic Interference (EMI) | Use twisted-pair shielded wire for sensing |

SSS

Q: Can I use a DC current shunt for AC welding? A: No. Standard shunts are designed for DC. For AC welding, you should use a Current Transformer (CT) or a Hall Effect sensor.

Q: Can I mount the shunt outside the welder case? A: Yes, this helps with cooling. However, you must build a protective cover to prevent electric shock and physical damage.

Q: What is the best way to clean a dirty shunt? A: Use dry compressed air to blow away metallic dust. If the terminals are oxidized, use a fine abrasive pad to brighten the copper before reconnecting.

Q: Why is my shunt reading negative? A: A shunt is a resistor, so it works both ways. If you see a negative number, simply swap the two small sensing wires.

Conclusion

Precision current measurement is not just a technical detail; it is the foundation of high-quality manufacturing. By selecting a properly sized dc current shunt, ensuring thermal stability, and following installation best practices, you guarantee stable arcs and consistent penetration.

At Leeyd , we empower industries with components that don’t compromise. Ready to stabilize your welding system? Contact our engineering team today.