LEEYD-Since 1985

Custom DC Shunt Resistor Manufacturer

Complete FL-Series (FL-2, FL-19 & More) | 1A - 30,000A | Manganin & Copper

Designed for Welding, EV, Energy Storage & General Industrial Power. 3-Day Prototyping.

38+ Years of Proven DC Shunt Manufacturing

With over 3 decades focused exclusively on DC current measurement, LEEYD is more than just a supplier. We support engineering and procurement teams across EV, energy storage, and industrial sectors who prioritize predictable performance ve technical reliability over the lowest price.

Full In-House Production: From Manganin resistance welding to final calibration, every step is completed internally to ensure 100% traceability.

Engineering-Level Customization: We don’t just sell standard parts. We adapt voltage drop, mounting dimensions, and terminal materials (Brass/Copper) to fit your specific system.

Flexible Supply Chain: Whether you need a prototype in 3 days or volume production for a welding machine factory, we deliver on time.

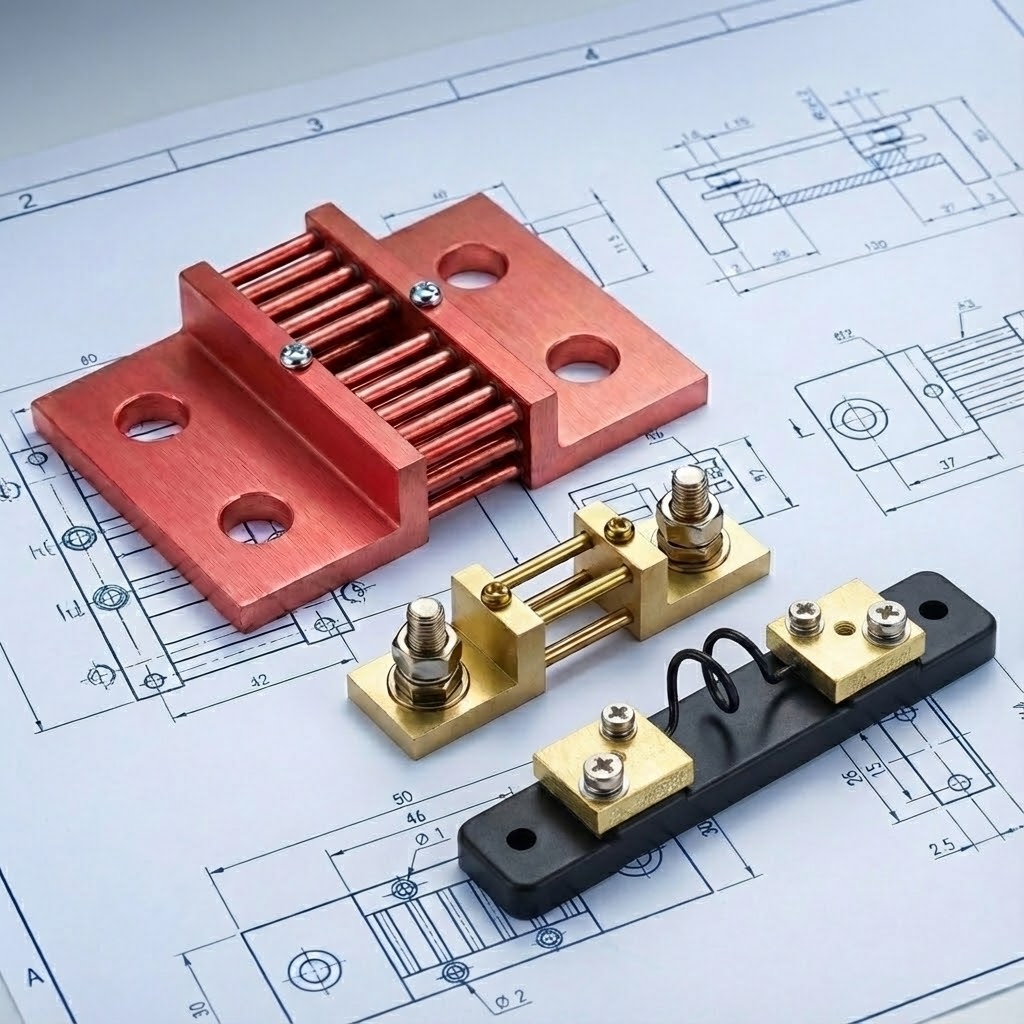

Engineering-Grade Customization

From Concept to Mass Production: Custom DC Shunt Resistors

Don’t compromise your system design with “off-the-shelf” limitations. Collaborate directly with LEEYD engineers to optimize voltage drop, mounting dimensions, and thermal management. Whether you need a low-TCR manganin element for a BMS or a rugged brass structure for a welder, we build it to your exact

- Wide Current Range: 1A to 30,000A (with overload protection design).

- Flexible Voltage Drop: Standard 75mV/50mV or custom 40mV - 300mV.

- Premium Materials: High-stability Manganin (CuMn12Ni) & Oxygen-Free Copper.

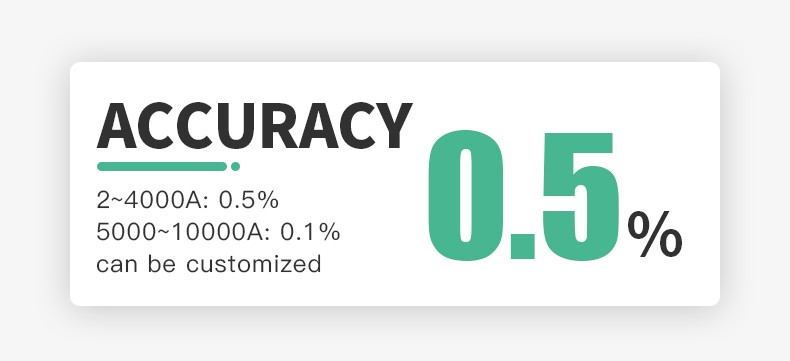

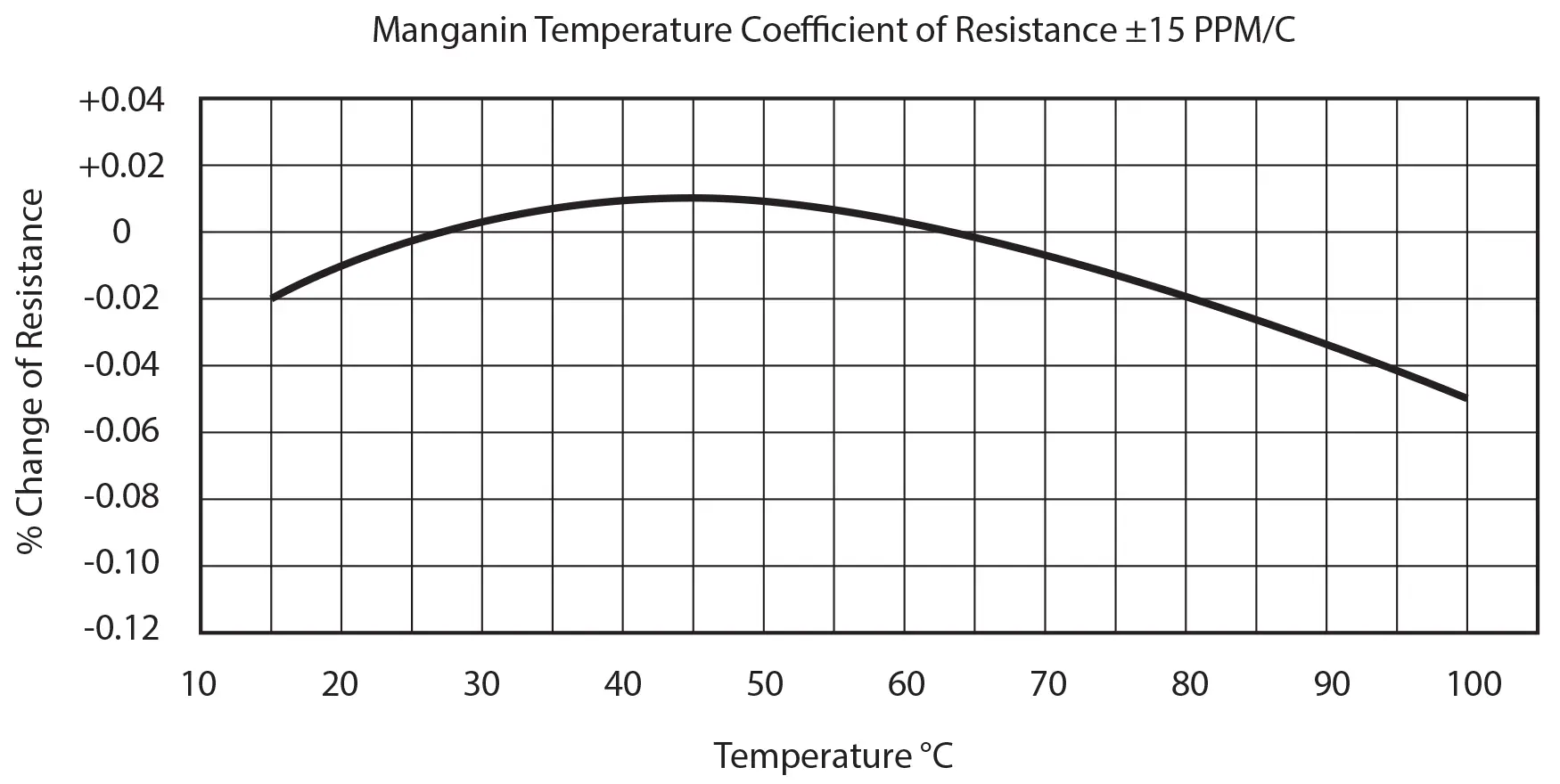

- Precision Class: 0.1/0.2 / 0.5 Accuracy with Low TCR (<25ppm>

- Fast Turnaround: Quote within 24h + Sample ready in 3 days.

Select Your DC Shunt Resistor Series | 1A to 30,000A

Note on Size: Physical dimensions scale with current rating to ensure safety and heat dissipation. From tiny 1A units for PCBs to massive 30,000A blocks for heavy industry, we manufacture the full spectrum. Choose the mounting structure below that fits your cabinet:

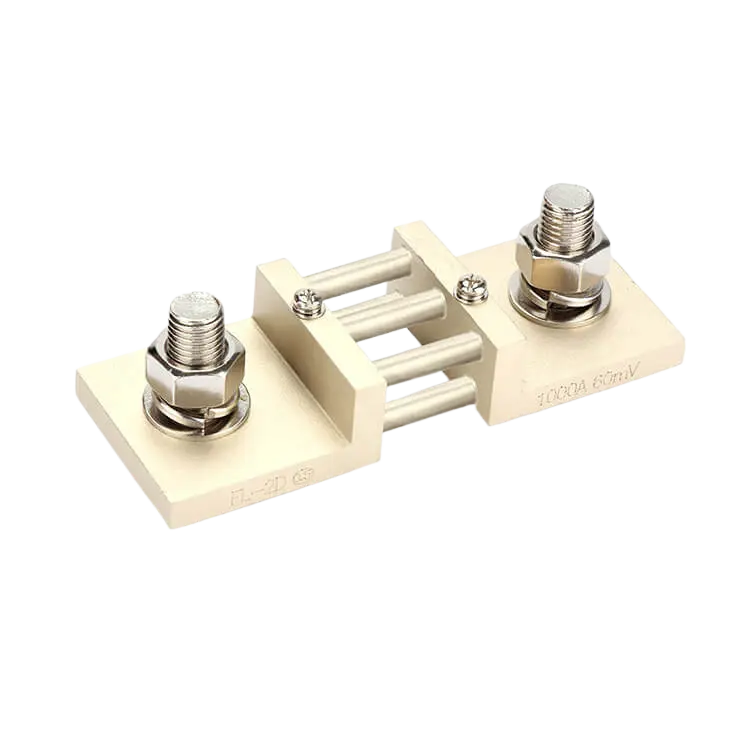

FL-2 DC Shunt

Standard DC shunt model with compact structure, suitable for high-current measurement in industrial power systems.

FL-19 DC Shunt

Heavy-duty DC shunt designed for stable current measurement under high load conditions.

FL-CR DC Shunt

Korean-style DC shunt featuring a distinct structural design commonly used in high-current applications.

FL-27 DC Shunt

Precision DC shunt model designed for instruments, meters, and calibration systems.

FL-21 DC Shunt

Standard DC shunt model covering a wide range of current ratings and mounting options.

FL-US DC Shunt

DC shunt model manufactured according to U.S. standard specifications.

FL-IN DC Shunt

DC shunt model commonly supplied for Indian market requirements.

FL-RU DC Shunt

Russia-type DC shunt with silver-welded construction for stable current measurement.

Sampling Shunt Resistor

Low-resistance shunt used for current sampling and sensing in power electronics.

U-Type Sampling Shunt

Compact U-shaped shunt designed for installations with limited space.

Beam Welding Shunt

Low-inductance DC shunt with beam-welded structure for reliable high-current performance.

Özelleştirilmiş

DC shunt solutions developed based on specific electrical and mechanical requirements.

Neden DC Akım Şöntlerimizi Seçmelisiniz

Engineered with controlled materials, stable structures, and verified test data — built for reliable DC current measurement.

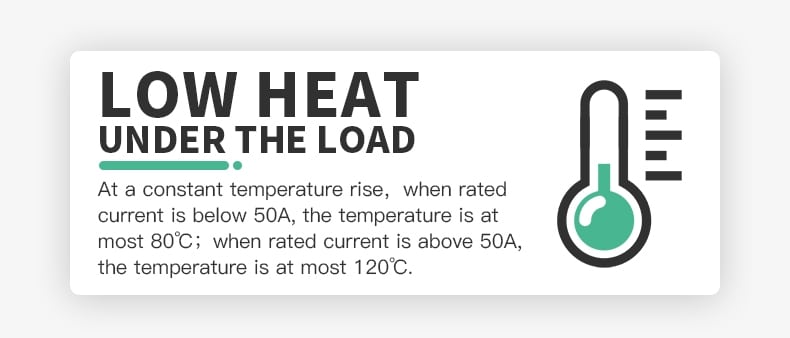

These performance values are based on real production models and verified through routine testing.

Actual specifications may vary by shunt type, current range, and voltage drop configuration.

Engineering Solutions for Critical Power Systems

In-depth technical insights on solving thermal drift, accuracy, and integration challenges in your industry.

Elektrikli Araçlar & BMS

Thermal Management for 800V EV Architectures

In high-voltage EV battery packs, high C-rate charging generates excessive heat at the shunt interface. This thermal stress induces resistance drift ($TCR$), causing State-of-Charge (SOC) estimation errors that impact range accuracy.

We utilize Electron-Beam Welded Manganin elements. This specialized joining process creates a homogeneous grain structure that caps the Temperature Coefficient of Resistance (TCR) at < 20ppm/°C, ensuring precise coulomb counting even under heavy loads.

Validation Data:

TCR: < 20ppm/°C (Premium Element)

Thermal EMF: < 2µV/°C

Compliance: AEC-Q200 Ready / REACH

> Recommended: FL-US Series or Custom EB-Welded Modules.

Yenilenebilir Enerji

Long-Term Stability for ESS & Solar Inverters

Energy Storage Systems (ESS) require a 15-20 year operational lifespan. Mechanical stress from daily thermal cycles causes “Aging Drift” in standard shunts, leading to permanent resistance shifts that compromise metering accuracy over time.

To minimize drift, our units undergo a Controlled Pre-Aging Process. By releasing internal lattice stress before calibration, we “lock in” the resistance value, ensuring consistent performance for grid-tied systems.

Validation Data:

Long-Term Stability: < 0.05% / year (Typical)

Overload Tolerance: 120% Rated Current (2 Hours) > Recommended: FL-US Series (A-A-55524 Standard).

Kaynak Makineleri

Signal Integrity in High-Noise Welding Environments

High-frequency switching in IGBT-based welders creates significant EMI (Electromagnetic Interference). Standard shunts can pick up inductive noise, distorting the feedback signal and resulting in unstable arcs.

The FL-19 Series features an optimized Low-Inductance Design. By refining the resistive path geometry, we minimize parasitic inductance to deliver a clean, true-RMS signal even in harsh electrical noise environments.

Validation Data:

Feature: Low-Inductance Structure

Construction: Rugged Silver-Brazed Joints

Impact Resistance: Tested for high vibration > Industry Standard: FL-19 Series.

Endüstriyel Otomasyon

Microsecond Response for Servo Drive Systems

In CNC machines and robotics, current control loops require instant feedback. Hysteresis or thermal lag in the sensing element leads to torque ripple and reduced machining precision.

We utilize high-purity copper-manganin alloys with Non-Inductive characteristics. This ensures the voltage drop mirrors current changes instantly (< 10µs response), enabling tighter PID control loops.

Validation Data:

Response Time: < 10µs

Linearity: ±0.2% (10% – 100% Load) > Recommended: FL-2 Series veya FL-US.

Güç Ekipmanları

Surge Protection for Critical Power & UPS

Data center UPS systems face unpredictable surge currents. A shunt fracture during a fault means a catastrophic loss of circuit protection when it is needed most.

Our Reinforced Brazing Technology ensures the joint between the resistive element and copper busbar withstands mechanical forces during short-circuit events without structural failure.

Validation Data:

Short-Time Withstand: 10x Rated Current (5s)

Joint Strength: High Tensile Strength Brazing > Recommended: FL-19 veya FL-2 Series.

Test ve Kalibrasyon

Metrology-Grade Calibration Standards

For instrument calibration and laboratory testing, standard “industrial accuracy” (0.5%) is insufficient. Engineers need a reference standard that remains virtually invariant regardless of temperature changes.

The FL-Standard Series uses Selected Manganin Foil, naturally aged to minimize lattice relaxation. This delivers laboratory-grade accuracy suitable for calibrating other measuring devices.

Validation Data:

Accuracy Class: 0.1% (Standard) / 0.2% (Option)

Self-Heating: Minimized by Oversized Design > Recommended: FL-27 veya FL-Standard.

DC Switchgear & Distribution

Current Sensing for DC Switchgear (Up to 1500V)

In DC distribution cabinets (PV/Traction), standard shunts often fail due to insufficient creepage distance or heat accumulation inside enclosed spaces.

We engineer switchgear-specific shunts with High-Creepage Insulating Bases specifically for 1500V DC applications. Combined with High-Surface-Area Radiating Fins, they ensure safe isolation and effective cooling even in compact IP54 cabinets.

Validation Data:

Rated Voltage: Up to 1500V DC

Dielectric Strength: Tested to 3000V AC (1 min) > Recommended: FL-2 Series (Base Mounted) or FL-US.

DC Fast Charging Infrastructure

Reliable Current Sensing for DC Fast Chargers (EVSE)

DC Charging Piles operate in harsh outdoor environments with frequent thermal cycling. The key challenge is maintaining structural integrity and heat dissipation under continuous high currents. Loose connections or overheating can lead to charging failures or safety hazards.

The FL-2 Series features a Solid Base-Mounted Design that provides superior mechanical stability against vibration and cable stress. Its massive copper/manganin structure utilizes the base as an additional heatsink, ensuring lower operating temperatures during prolonged charging sessions compared to lightweight alternatives.

Validation Data:

Structure: Base-mounted for stability

Overload: 120% Rated Current (2 Hours)

Heat Dissipation: Enhanced by mounting base

> Industry Standard: FL-2 Series (Most widely used). (Available with Class 0.5 accuracy for metering)

Let’s Solve Your DC Shunt Requirements — Together

Work directly with an experienced DC shunt specialist who understands both engineering requirements and procurement realities.

From custom DC shunt specifications to urgent samples and production schedules, we support engineers and procurement teams with clear answers, fast response, and practical solutions.

Whether you are selecting a standard model, adapting a shunt for a specific application, or validating performance for your system, you’ll be speaking with real people who know DC current measurement — not a generic sales desk.

Manufacturing You Can Rely On

From prototyping to mass production, every DC shunt is manufactured in-house under controlled ISO processes — ensuring consistent quality, stable lead times, and full traceability.

Critical steps such as resistance welding, manganin element assembly, calibration, and final inspection are all completed internally. This allows us to maintain tight tolerances, reliable performance, and repeatable results across batches.

For engineering teams, this means predictable electrical characteristics.

For procurement teams, it means dependable delivery and fewer surprises — even during peak production periods.

Our Certifications = Your Confidence in Us

All LEEYD DC shunts are manufactured with ROHS, REACH & CA Prop 65–compliant materials — safe, tested, and ready for global markets.

Material Compliance That Keeps You Market-Ready

For global buyers and engineering teams, compliance is not just documentation — it’s about reducing risk and keeping projects moving.

At LEEYD, ROHS, REACH, and CA Prop 65 compliance are built directly into every DC current shunt we manufacture, from material selection to final inspection. This helps you meet regulatory requirements, pass audits, and avoid delays in customs or customer approval.

ROHS Compliant

Manufactured with approved materials, free from restricted substances, ensuring smooth access to EU and global markets.

REACH Compliant

Materials are traceable and aligned with EU chemical safety regulations, supporting long-term compliance across Europe.

CA Prop 65 Ready

Screened for regulated substances to support sales in the U.S. market without warning-label complications.

📄 Market-specific test reports and supporting documents are available within 24 hours upon request.

What Buyers Ask Before Ordering

Absolutely.

We specialize in custom DC current shunts, supporting adjustments in:

Rated current & voltage drop (40mV / 50mV / 60mV / 75mV / 100mV)

Accuracy class (down to 0.1%)

Terminal type, size, hole position, and mounting layout

Material selection (manganin, copper alloys, brass)

Labeling, marking, and packaging requirements

You can send us a drawing, datasheet, or even a reference sample.

Our engineers will either match it directly or suggest a technically safer alternative.

Yes — and this is where most long-term projects start.

We regularly work directly with R&D, electrical engineers, and system designers during:

New product development

Prototype validation

Performance optimization under thermal or overload conditions

Our team provides drawing confirmation, tolerance review, and application advice, so issues are solved before mass production, not after.

Quality control is fully in-house.

Every DC shunt goes through:

Incoming material inspection

Resistance & voltage drop verification

Thermal rise and overload performance checks

Final inspection before shipment

We follow ISO-based production processes, and test reports can be provided upon request — especially for EV, energy storage, and industrial power applications.

Samples: usually 3–5 working days

Small batch orders: 7–15 days

Mass production: confirmed based on quantity and customization level

For urgent projects, we can prioritize production — just let us know your deadline in advance.

We don’t disappear after shipment.

If there’s any issue related to spec mismatch, performance deviation, or damage, we will:

Analyze the root cause with our engineers

Propose a corrective solution

Replace or remake parts when responsibility is on our side

You’ll always have a real person handling the case, not an automated reply.

Yes.

We support low MOQ and trial orders, even from 1 piece, especially for:

Prototyping

Testing new designs

Supplier qualification

Many of our long-term customers started with a small trial before scaling up.

We ship worldwide using DHL, FedEx, UPS, or customer-appointed forwarders.

Export packaging is standard, and all shipments include:

Commercial invoice

Packing list

Compliance documents if required (RoHS / REACH / Prop 65)

We regularly ship to USA, Europe, India, Japan, Korea, and the Middle East.

Our DC shunts are widely used in:

EV & BMS systems

Energy storage & inverters

Welding machines

UPS & industrial power supplies

Test & calibration equipment

If you share your system type or measurement method, we’ll confirm compatibility or recommend the most suitable model.

Most clients come to us for one of three reasons:

Faster response & clearer communication

Better support for customization

More stable quality across batches

We may not always be the cheapest — but we focus on being reliable, responsive, and technically accountable.

Get What You Need — In 3 SimpleSteps

We keep the process straightforward.

Share your requirements, and our engineering team will handle the technical details — from sample to mass production.

Whether you’re validating a prototype or sourcing for long-term supply, we’ll guide you step by step with clear timelines and fast feedback.

Send Your Specs or Application Details

Drawings, datasheets, target current, voltage drop, or usage scenario — even partial info is fine.

Receive Quotation & Technical Confirmation

You’ll get pricing, lead time, and engineering suggestions if optimization is needed.

Approve + Start Production

Samples or mass production starts only after you confirm everything clearly.

Hadi Konuşalım

Consumer Electronics and Power Electronics

In the consumer electronics and power electronics industry, Hall sensors are ushering in a new era of smart technology. Their applications in smartphones and tablets, such as magnetic switches and screen rotation detection, offer users a more intuitive and convenient operating experience. Meanwhile, in current detection and battery management systems, Hall sensors ensure safe operation and energy efficiency management of devices, meeting the demands of modern life for intelligent and sustainable technology.