Sensors are very important in the ever-changing, rapid technological environment in the automotive world to consumer electronics. Of these, the Hall sensors have become increasingly popular because of their accuracy, reliability and noncontact functionality.

Hall sensors are typically popular among engineers and designers when accuracy, stability and flexibility is important and hall sensors are used to substitute conventional sensing devices

Understanding Hall Sensors

Definition and Working Principle

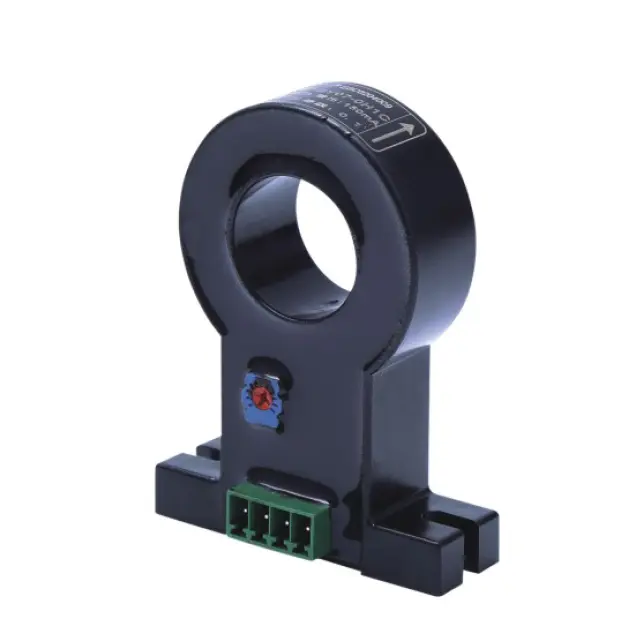

The Hall effect is a method of using magnetic fields to produce electrical signals with the help of Hall sensors. When a path that carries current is subjected to a magnetic field that is perpendicular to the conductor, a voltage is induced across the conductor, this is the operating principle of Hall sensors

Types of Hall Sensors

- Digital Hall Sensors: Provide on/off signals for presence detection.

- Linear Hall Sensors: Offer continuous voltage output proportional to magnetic field strength.

- Omnipolar Hall Sensors: Detect both north and south magnetic poles, enhancing flexibility.

Key Applications

- Automotive: speedometers, brushless DC motors

- Industrial automation: robotic arms, conveyor systems

- Consumer electronics: smartphones, laptops, gaming devices

- Energy sector: current measurement in power electronics

Comparing Hall Sensors with Other Sensing Devices

| Sensor Type | Advantages | Limitations |

| Resistive | Simple design, low cost | Less precise, prone to wear and tear |

| Inductive | Reliable for metal detection | Bulkier, limited to metallic objects |

| Optical | High-speed detection | Sensitive to dust, dirt, and environmental factors |

| Hall Sensor | Non-contact, durable, precise | Requires magnetic field source |

Unlike resistive, inductive, or optical sensors, Hall sensors provide consistent accuracy and reliability even in harsh or dirty environments.

Advantages of Hall Sensors

Hall sensors do not come into contact with the object of measurement. Due to lack of physical contact, parts do not wear out over time. This implies that the sensor has a longer lifespan and requires fewer repairs.

These sensors generate very precise measurements even in cases where objects are moving at high speed. Hall sensors give good results every time whether it is speed or position.

Hall sensors are robust and small. They are able to cope with extreme environments such as heat, dust and vibration thus suitable for extreme environments.

Hall sensors may be applied in numerous areas. They can be found in vehicles (speed and throttle sensors), factories (machines and robots), and in electronic gadgets (smartphones, laptops) and energy systems (measuring electricity flow).

Hall sensors are not very expensive and are easily incorporated into an existing system. They need fewer repairs, and ensure smooth running of your devices, and not only save time, but also save money.

Practical Applications Where Hall Sensors Excel

Automotive

Hall sensors are also popular in automobiles enabling the automobiles to operate more efficiently. They assist in measurement of throttle position, control of brushless DC motors and speed. This guarantees smooth driving and performance.

Endüstriyel Otomasyon

Hall sensors facilitate the correct work of machines in factories and production lines. They keep track of the positions of the robotic arms, ensure the movement of the conveyor belt and verify the well-being of the machinery to avoid failures.

Consumer Electronics

Hall sensors bring intelligence to common devices. They are able to identify the open or closed state of the lids in laptops and smartphones. They are also employed in game controllers and devices in order to enhance accuracy and reactivity.

Energy Sector

Hall sensors are important in the control of electricity. They are used in the measurement of power converters and to monitor renewable energy systems to ensure that the energy is used safely and efficiently.

Key Considerations When Choosing Hall Sensors

To select a Hall sensor, the first thing to do is to make sure that the sensor should be sensitive and fast. Ensure it is able to measure the required parameters accurately.

Another thing to consider is the place of use. Is it able to withstand heat, dust or moisture? Ensure that it is compatible with your other electronics and that it will not require so many repairs thus ensuring a long life.

Conclusion

Hall sensors are always efficient in comparison to traditional sensors in projects and activities that require accuracy, reliability, and multitasking. Their non-contact operation,small size and precision make them an ideal selection in application in automotive applications to industrial automation.

Explore high-quality Hall sensors for precision applications at LEEYDTECH and elevate the reliability of your systems.

FAQs

Q. How are Hall sensors different from resistive sensors?

Hall sensors work without touching anything, so they last longer and are more accurate. Resistive sensors need contact and can wear out.

Q. Can Hall sensors work in tough conditions?

Yes. They can handle heat, dust, and moisture, so they work well in factories and outdoors.

Q. Are Hall sensors used in cars?

Yes. They help measure speed, throttle positions, and control motors in vehicles.

Q. What types of Hall sensors are there?

There are three main types:

- Digital: on/off detection

- Linear: measures strength of magnets

- Omnipolar: detects magnets of any pole