LEEYD-Since 1985

High-Precision DC Current Shunt Manufacturer

Designed for EV, Energy Storage & Industrial Power Applications

3-Day Prototyping · ±0.1% Accuracy · Custom DC Shunt Solutions

Proven DC Shunt Manufacturing Experience

With over 38 years focused exclusively on DC shunt manufacturing, LEEYD supports engineering and procurement teams across EV, energy storage, and industrial power projects worldwide.

Our experience covers a wide range of DC current measurement requirements — from standard shunt models to fully customized designs based on current range, voltage drop, mounting structure, and application environment.

All DC shunts are produced in-house, allowing fast prototyping, stable quality control, and full traceability with test reports. We support low-volume trials, tight project timelines, and consistent delivery even during peak production periods.

Our customers choose LEEYD not because we promise the lowest price, but because they need predictable performance, clear technical communication, and a supplier they can rely on throughout the entire project lifecycle.

Engineering-Level Customization

Custom DC Shunts Built for Your Specs

Designed for engineers who need precise, stable current measurement —

from low-current sensing to high-power industrial systems.

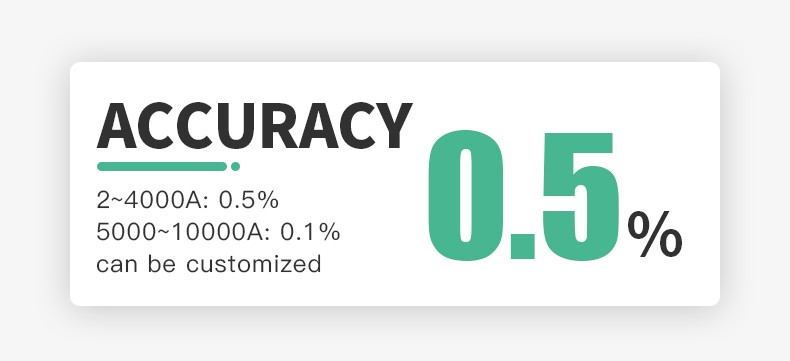

- Accuracy up to 0.1% — verified for critical current measurement

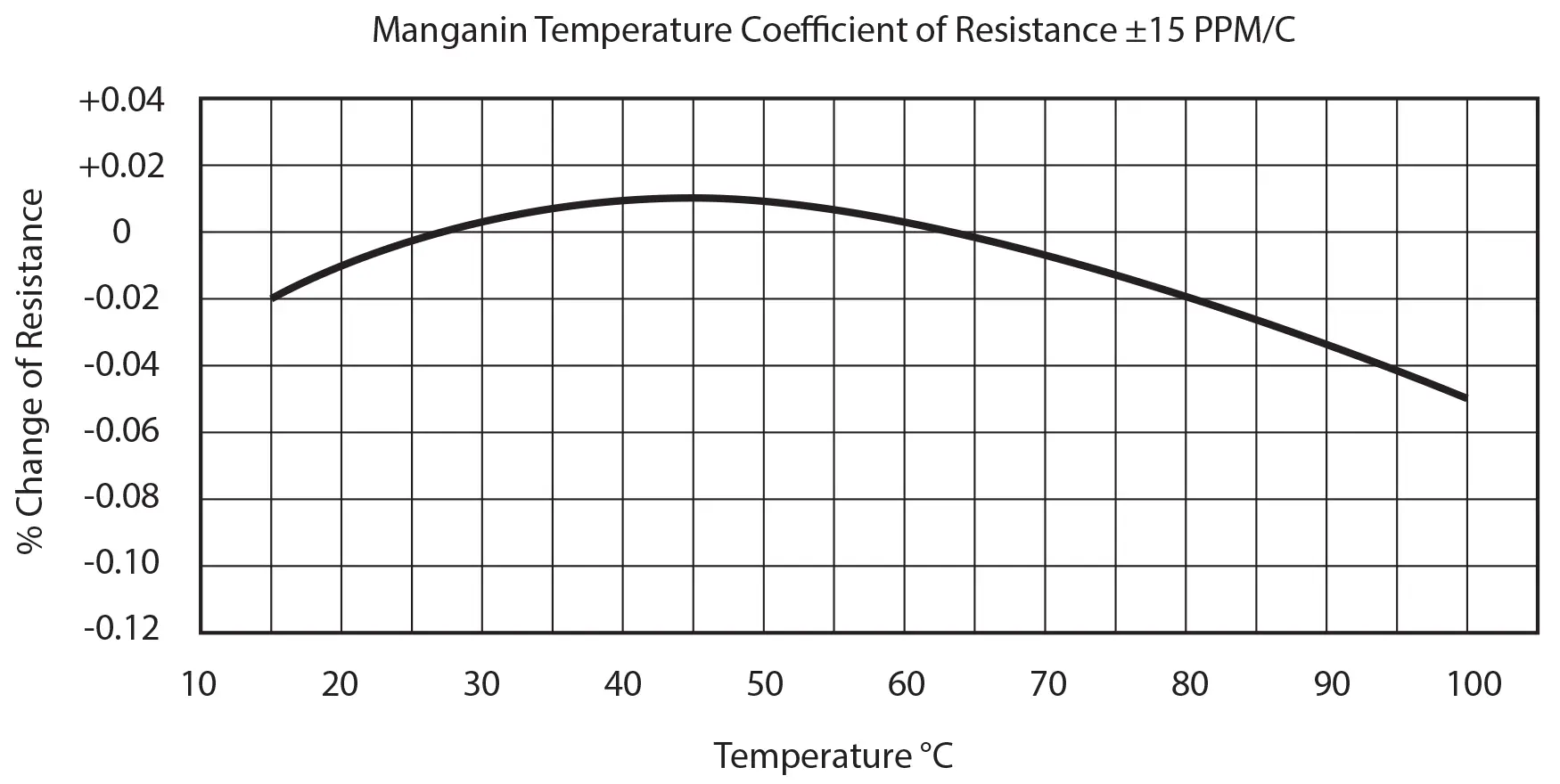

- Low thermal drift (<25 ppm/°C) for long-term stability under load

- Wide current range: from 1A to 30,000A

- Selectable voltage drop: 40mV / 50mV / 60mV / 75mV / 100mV

- Material options: copper or brass with manganin element

- Custom terminals, layouts & markings — ready for system integration

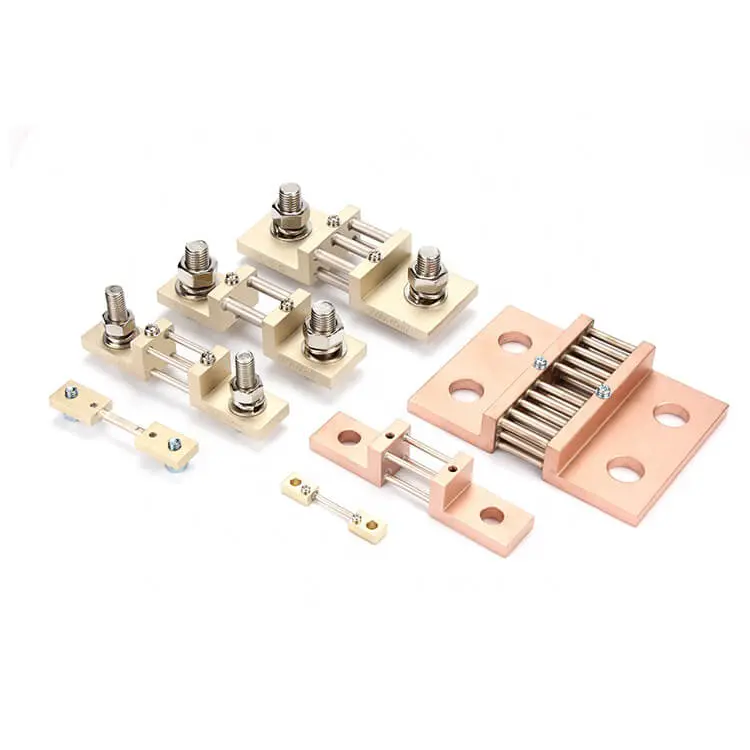

Our Standard DC Shunt Models

A selection of commonly used DC shunt models, covering different structures, current ranges, and installation requirements.

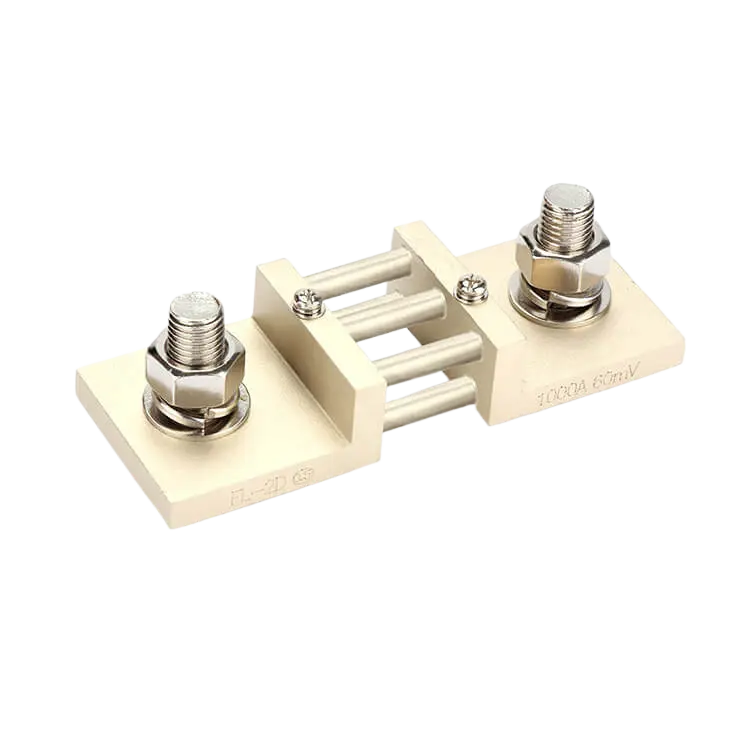

FL-2 DC Shunt

Standard DC shunt model with compact structure, suitable for high-current measurement in industrial power systems.

FL-19 DC Shunt

Heavy-duty DC shunt designed for stable current measurement under high load conditions.

FL-CR DC Shunt

Korean-style DC shunt featuring a distinct structural design commonly used in high-current applications.

FL-27 DC Shunt

Precision DC shunt model designed for instruments, meters, and calibration systems.

FL-21 DC Shunt

Standard DC shunt model covering a wide range of current ratings and mounting options.

FL-US DC Shunt

DC shunt model manufactured according to U.S. standard specifications.

FL-IN DC Shunt

DC shunt model commonly supplied for Indian market requirements.

FL-RU DC Shunt

Russia-type DC shunt with silver-welded construction for stable current measurement.

Sampling Shunt Resistor

Low-resistance shunt used for current sampling and sensing in power electronics.

U-Type Sampling Shunt

Compact U-shaped shunt designed for installations with limited space.

Beam Welding Shunt

Low-inductance DC shunt with beam-welded structure for reliable high-current performance.

客製化

DC shunt solutions developed based on specific electrical and mechanical requirements.

為何選擇我們的直流電流分流器

Engineered with controlled materials, stable structures, and verified test data — built for reliable DC current measurement.

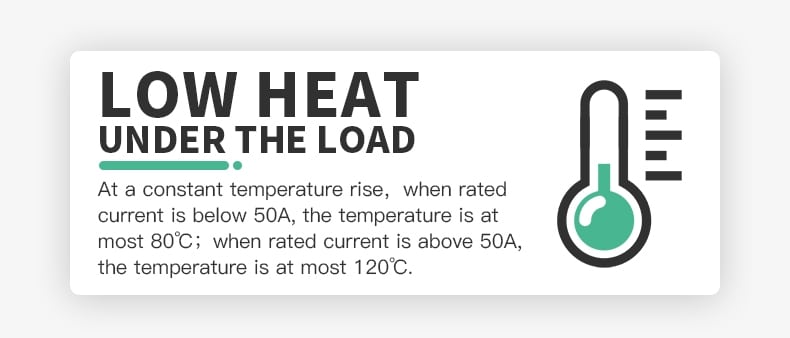

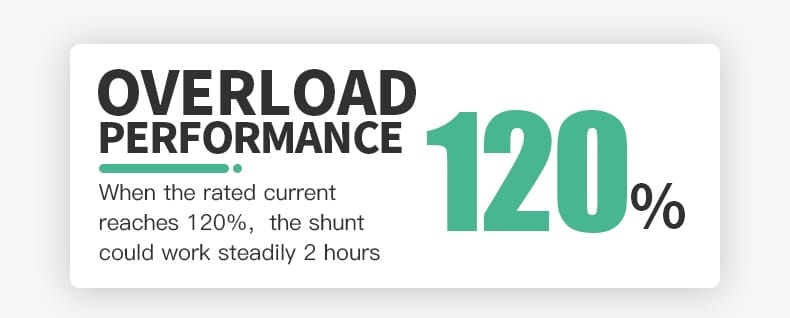

These performance values are based on real production models and verified through routine testing.

Actual specifications may vary by shunt type, current range, and voltage drop configuration.

Where Our DC Shunts Work Best

Trusted in energy, mobility, automation, and precision control systems for reliable DC current measurement.

焊接機

Stable DC current feedback for arc stability and thermal control in welding machines.

電動車與 BMS

Accurate monitoring of charge and discharge current in EV battery systems and BMS for safety, efficiency, and protection.

電力設備

Used in UPS, inverters, and industrial power equipment for real-time DC current monitoring and system protection.

可再生能源

Ensures accurate DC current measurement in PV inverters, MPPT controllers, and energy storage systems.

工業自動化

Applied in CNC machines, servo drives, and industrial automation systems requiring stable current feedback.

測試與校正

Precision-grade DC shunts for laboratory testing, metering calibration, and R&D applications.

Let’s Solve Your DC Shunt Requirements — Together

Work directly with an experienced DC shunt specialist who understands both engineering requirements and procurement realities.

From custom DC shunt specifications to urgent samples and production schedules, we support engineers and procurement teams with clear answers, fast response, and practical solutions.

Whether you are selecting a standard model, adapting a shunt for a specific application, or validating performance for your system, you’ll be speaking with real people who know DC current measurement — not a generic sales desk.

Manufacturing You Can Rely On

From prototyping to mass production, every DC shunt is manufactured in-house under controlled ISO processes — ensuring consistent quality, stable lead times, and full traceability.

Critical steps such as resistance welding, manganin element assembly, calibration, and final inspection are all completed internally. This allows us to maintain tight tolerances, reliable performance, and repeatable results across batches.

For engineering teams, this means predictable electrical characteristics.

For procurement teams, it means dependable delivery and fewer surprises — even during peak production periods.

Our Certifications = Your Confidence in Us

All LEEYD DC shunts are manufactured with ROHS, REACH & CA Prop 65–compliant materials — safe, tested, and ready for global markets.

Material Compliance That Keeps You Market-Ready

For global buyers and engineering teams, compliance is not just documentation — it’s about reducing risk and keeping projects moving.

At 利雅得, ROHS, REACH, and CA Prop 65 compliance are built directly into every DC current shunt we manufacture, from material selection to final inspection. This helps you meet regulatory requirements, pass audits, and avoid delays in customs or customer approval.

ROHS Compliant

Manufactured with approved materials, free from restricted substances, ensuring smooth access to EU and global markets.

REACH Compliant

Materials are traceable and aligned with EU chemical safety regulations, supporting long-term compliance across Europe.

CA Prop 65 Ready

Screened for regulated substances to support sales in the U.S. market without warning-label complications.

📄 Market-specific test reports and supporting documents are available within 24 hours upon request.

What Buyers Ask Before Ordering

Absolutely.

We specialize in custom DC current shunts, supporting adjustments in:

Rated current & voltage drop (40mV / 50mV / 60mV / 75mV / 100mV)

Accuracy class (down to 0.1%)

Terminal type, size, hole position, and mounting layout

Material selection (manganin, copper alloys, brass)

Labeling, marking, and packaging requirements

You can send us a drawing, datasheet, or even a reference sample.

Our engineers will either match it directly or suggest a technically safer alternative.

Yes — and this is where most long-term projects start.

We regularly work directly with R&D, electrical engineers, and system designers during:

New product development

Prototype validation

Performance optimization under thermal or overload conditions

Our team provides drawing confirmation, tolerance review, and application advice, so issues are solved before mass production, not after.

Quality control is fully in-house.

Every DC shunt goes through:

Incoming material inspection

Resistance & voltage drop verification

Thermal rise and overload performance checks

Final inspection before shipment

We follow ISO-based production processes, and test reports can be provided upon request — especially for EV, energy storage, and industrial power applications.

Samples: usually 3–5 working days

Small batch orders: 7–15 days

Mass production: confirmed based on quantity and customization level

For urgent projects, we can prioritize production — just let us know your deadline in advance.

We don’t disappear after shipment.

If there’s any issue related to spec mismatch, performance deviation, or damage, we will:

Analyze the root cause with our engineers

Propose a corrective solution

Replace or remake parts when responsibility is on our side

You’ll always have a real person handling the case, not an automated reply.

Yes.

We support low MOQ and trial orders, even from 1 piece, especially for:

Prototyping

Testing new designs

Supplier qualification

Many of our long-term customers started with a small trial before scaling up.

We ship worldwide using DHL, FedEx, UPS, or customer-appointed forwarders.

Export packaging is standard, and all shipments include:

Commercial invoice

Packing list

Compliance documents if required (RoHS / REACH / Prop 65)

We regularly ship to USA, Europe, India, Japan, Korea, and the Middle East.

Our DC shunts are widely used in:

EV & BMS systems

Energy storage & inverters

Welding machines

UPS & industrial power supplies

Test & calibration equipment

If you share your system type or measurement method, we’ll confirm compatibility or recommend the most suitable model.

Most clients come to us for one of three reasons:

Faster response & clearer communication

Better support for customization

More stable quality across batches

We may not always be the cheapest — but we focus on being reliable, responsive, and technically accountable.

Get What You Need — In 3 SimpleSteps

We keep the process straightforward.

Share your requirements, and our engineering team will handle the technical details — from sample to mass production.

Whether you’re validating a prototype or sourcing for long-term supply, we’ll guide you step by step with clear timelines and fast feedback.

Send Your Specs or Application Details

Drawings, datasheets, target current, voltage drop, or usage scenario — even partial info is fine.

Receive Quotation & Technical Confirmation

You’ll get pricing, lead time, and engineering suggestions if optimization is needed.

Approve + Start Production

Samples or mass production starts only after you confirm everything clearly.