DC shunts play a crucial role in electric current measurement. They are essential components that involve a precision resistor positioned parallel to a measuring instrument. The main purpose of DC shunts is to establish a pathway with low resistance, which permits a fraction of the electrical current to flow through. This configuration facilitates the precise assessment of substantial currents indirectly by observing the minor voltage reduction across the shunt resistor. In simpler terms, DC shunts serve as precise tools for measuring electric currents accurately. Their strategic placement alongside measuring devices ensures efficient and reliable current measurement processes.

To comprehend the intricacies of DC current shunts, it is crucial to first understand Ohm’s law, which forms the foundation of their operation. Ohm’s law asserts that the current flowing through a conductor connecting two points is directly proportional to the voltage applied across these points and inversely proportional to the resistance in the path. DC current shunts, designed as low-resistance components, facilitate the passage of most of the current flowing through them while inducing minimal voltage drop. This characteristic of shunts is essential in ensuring that they do not significantly impact the overall impedance of the circuit in which they are integrated. By allowing the current to bypass them efficiently, shunts play a critical role in maintaining the integrity and functionality of the circuit.

How DC Current Shunts Work: The Principle of Operatio

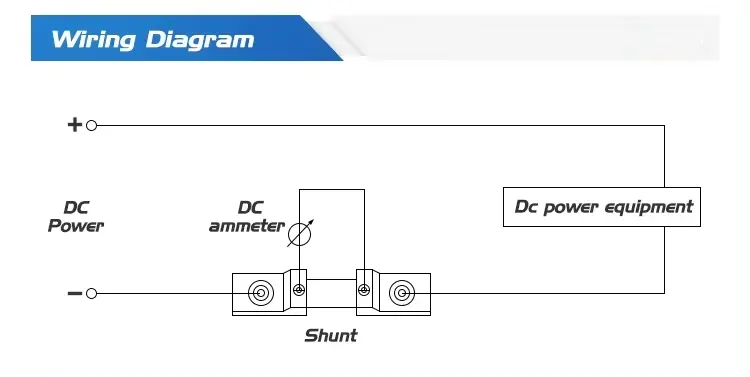

In the functioning of direct current (DC) current shunts, the process involves measuring the voltage drop across the shunt, which is subsequently utilized in calculating the current passing through it. Given that the resistance of the shunt is a well-known and consistent value, determining the current flow through it can be achieved through the application of Ohm’s Law, specifically the formula I = V/R. Here, ‘I’ represents the current, ‘V’ denotes the voltage, and ‘R’ stands for the resistance.

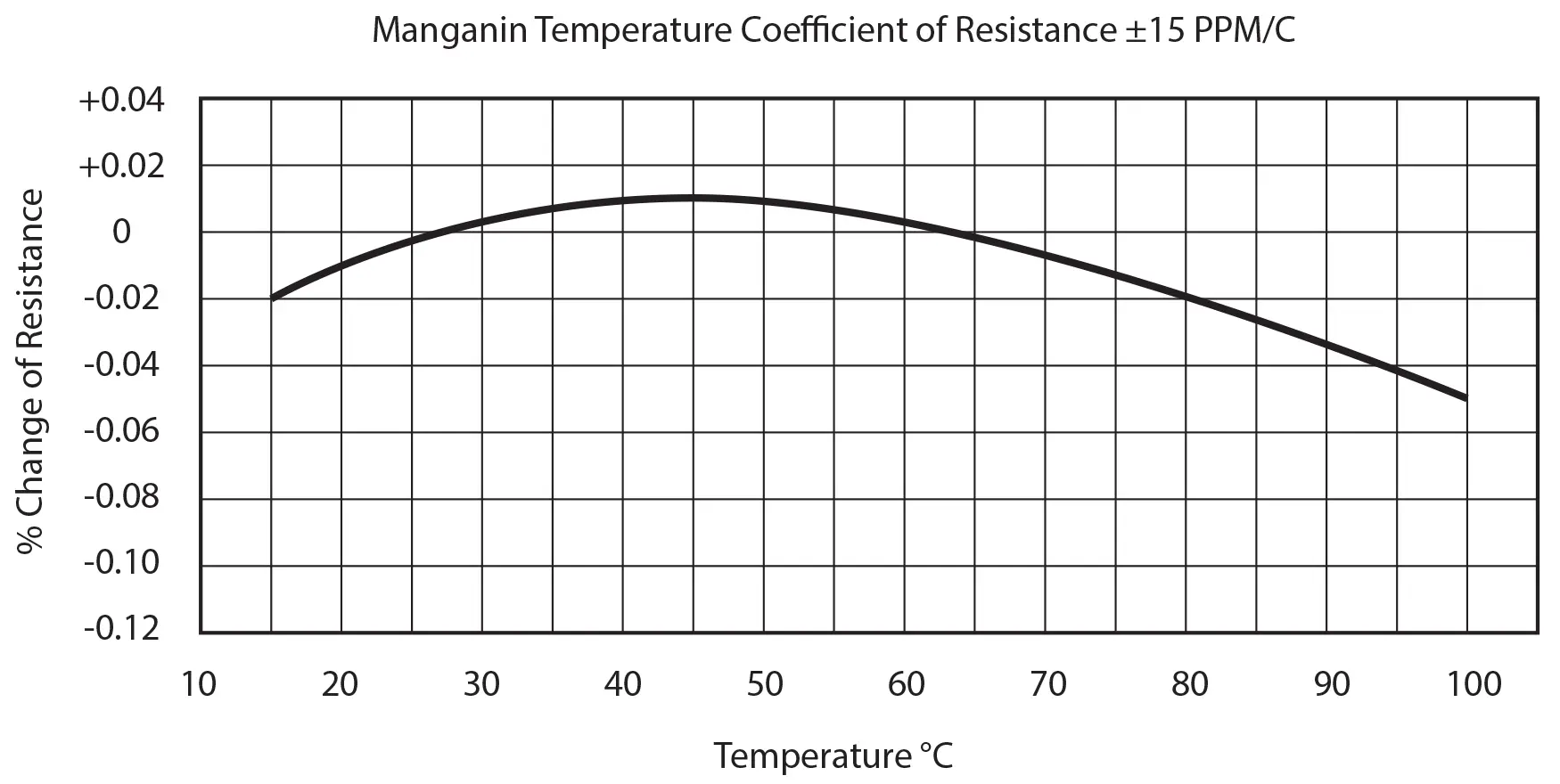

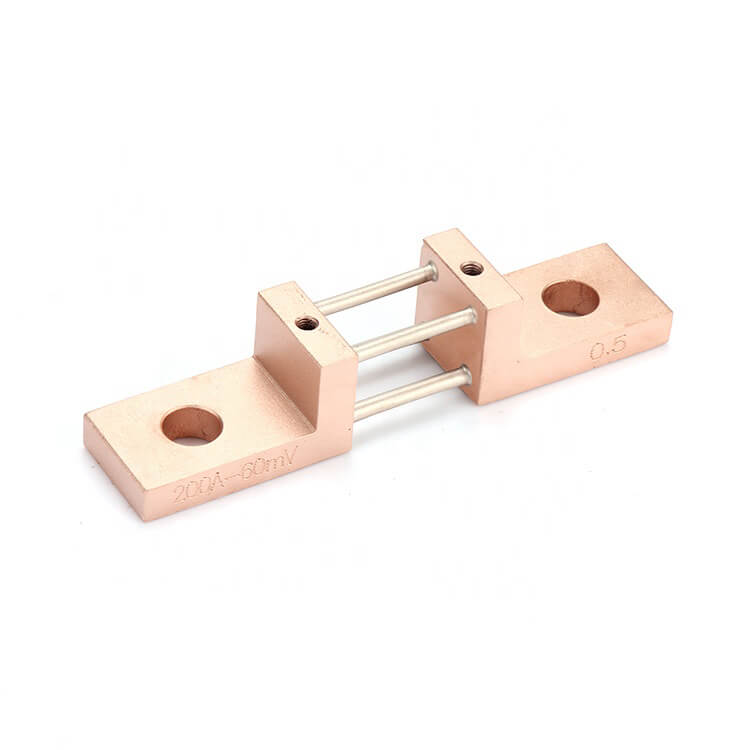

Precision plays a critical role in the production of DC current shunts, where even minor deviations in resistance value can have a direct impact on the precision of current readings. These shunts are commonly crafted from materials such as manganin or constantan, chosen for their minimal temperature coefficients and resilience against external elements like temperature and humidity, which have the potential to influence resistance levels significantly. The careful selection of these materials is essential to ensure that the shunts maintain their accuracy and reliability in various environmental conditions. The stability and consistency of the resistance properties of manganin and constantan make them ideal choices for manufacturing DC current shunts.

Key Types and Specifications of DC Current Shunts

DC current shunts are available in a variety of types and sizes, with each designed to cater to specific applications and ranges of current. The two main categories include fixed shunts and adjustable shunts. Fixed shunts maintain a steady resistance and are utilized in scenarios where the current range is consistent and predictable. Conversely, adjustable shunts provide adaptability, allowing for customization to varying ranges, which makes them well-suited for applications that demand versatility. Fixed shunts are preferred when a stable resistance value is required, while adjustable shunts offer the advantage of flexibility to adjust and accommodate different current ranges as needed. The choice between fixed and adjustable shunts depends on the specific requirements of the application in terms of current range variability.

When choosing a DC current shunt, it is essential to carefully assess specific specifications such as the current rating, accuracy level, resistance value, thermal capacity, and physical size. The current rating of the shunt should be commensurate with the maximum anticipated current flow within the circuit to ensure optimal performance. Moreover, accuracy plays a pivotal role in guaranteeing precise and reliable measurements in electrical applications.

Common Applications and Importance of DC Current Shunts in Electrical Systems

DC current shunts play a pivotal role in a diverse array of applications, spanning from industrial complexes to the realm of renewable energy and automotive sectors. These shunts are indispensable in industrial environments, where they serve the crucial function of monitoring the performance and effectiveness of high-powered machinery and electrical setups. Additionally, they hold notable significance in battery management and charging systems, where the accurate measurement of current is essential to ensure operational safety and optimize efficiency. By accurately gauging current flow, DC current shunts aid in maintaining the integrity and reliability of various systems, ultimately contributing to enhanced overall performance and safety across different sectors.

In the realm of renewable energy, specifically within solar and wind power setups, DC current shunts serve a crucial function in overseeing power distribution and incorporating systems into the grid. Their precision and dependability are fundamental for guaranteeing the efficient operation of these setups. Moreover, in the domain of automotive technology, particularly in electric vehicles, the utilization of DC current shunts is vital for managing battery functionalities and regulating the energy transmitted to the motor. These components act as pivotal instruments in controlling and optimizing the performance of both renewable energy systems and electric vehicles, showcasing their significance in enhancing overall efficiency and functionality.

Advancements and Innovations in DC Current Shunt Technology

The domain of DC current shunts is in a constant state of evolution, with a primary focus on improving precision, longevity, and adaptability. Recent advancements have seen a shift towards incorporating digital technologies, leading to the development of intelligent shunts that are IoT-enabled and capable of providing extensive data and valuable insights about electrical systems. These innovative shunts go beyond just measuring current; they also have the capability to monitor essential parameters such as temperature and voltage, offering a holistic perspective on the overall health and performance of the system. This integration of digital advancements not only enhances the functionality of the shunts but also contributes significantly to the efficiency and effectiveness of electrical measurements and monitoring processes.

Innovative advancements are also being made in the field of shrinking shunts. With the continuous trend towards smaller and more energy-efficient electronic devices, there is a rising demand for compact, high-accuracy DC current shunts. The development of miniaturized shunts is aimed at catering to the need for precise performance within limited spaces. These specialized shunts are engineered to seamlessly integrate into increasingly constricted environments while upholding their operational excellence.

DC current shunts play a pivotal role in accurately measuring and controlling electrical currents across a wide range of applications. It is essential to comprehend the fundamental principles of operation, as well as explore their advanced applications and recent innovations to fully exploit the benefits they offer in the design and upkeep of electrical systems. With the evolution of technology, the industry can anticipate the emergence of more intricate DC current shunt solutions, enhancing our ability to efficiently and safely monitor and regulate electrical energy in various settings. Understanding and embracing the significance of DC current shunts not only ensures precise measurements but also supports the overall efficiency and safety of electrical operations. This continual advancement in shunt technology is instrumental in pushing the boundaries of electrical management towards improved performance and reliability.